Org. Synth. 2023, 100, 99-112

DOI: 10.15227/orgsyn.100.0099

α-Arylation of Cyclopentanones by Palladium/Enamine Cooperative Catalysis

Submitted by Yibin Xue, Arjuna Parsad, and Guangbin Dong*

1Checked by Jaejoong Han, Masanori Nagatomo, and Masayuki Inoue

1. Procedure (Note 1)

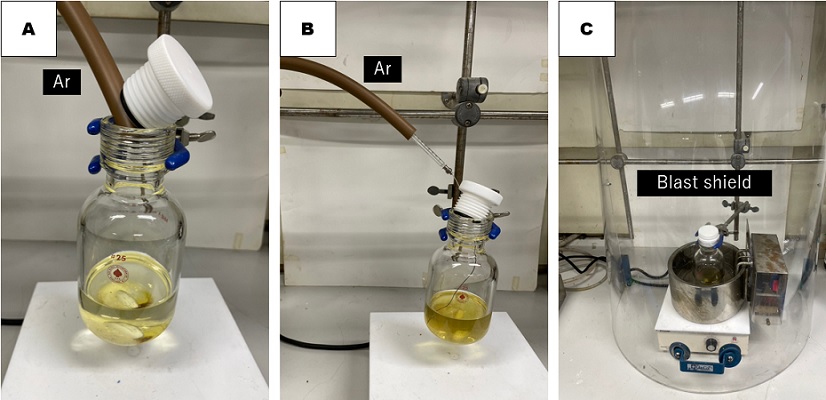

A. 2-(4-Acetylphenyl)cyclopentan-1-one (4). A 325 mL heavy-walled pressure vessel (Note 2), equipped with a Teflon-coated, football-shaped magnetic stir bar (24 mm × 10 mm), is charged with cyclopentanone (1.68 g, 20.0 mmol, 1 equiv) (Note 3), 4'-bromoacetophenone (5.18 g, 26.0 mmol, 1.3 equiv) (Note 4), palladium(II) acetate (45 mg, 0.20 mmol, 1 mol%) (Note 5), tri(o-tolyl)phosphine (122 mg, 0.40 mmol, 2 mol%) (Note 6), sodium acetate (1.64 g, 20.0 mmol, 1 equiv) (Note 7), pyrrolidine (0.50 mL, 6.0 mmol, 30 mol%) (Note 8), 1,1,3,3-tetramethylbutylamine (0.96 mL, 6.0 mmol, 30 mol%) (Note 9), and 100 mL of 1,4-dioxane (Note 10) under air. Pyrrolidine and 1,1,3,3-tetramethylbutylamine are added using a 1 mL disposable syringe, and 1,4-dioxane is added using a 64 mL disposable syringe. The atmosphere in the vessel is replaced by flowing argon into the vessel at a flow rate of 7000 mL/min for 30 sec (Figure 1A). Argon gas (260 mL/min) is then bubbled through the solution with a syringe needle for 20 min (Figure 1B). The vessel is immediately capped with a Teflon bushing and sealed with Teflon tape (Note 11) (Figure 1C).

Figure 1. Reaction set-up; (A) Blowing the vessel with argon gas; (B) Bubbling the solution with argon gas; (C) After inserting the vessel into an oil bath (photos provided by checkers)

A blast shield is placed in front of the closed vessel. The reaction mixture is stirred (900 rpm) at 130 °C which is the temperature of an oil bath. The color of the solution changes from yellow (Figure 2A) to red after 15 min (Figure 2B), then to dark brown after 24 h (Figure 2C). After being stirred for 24 h at 130 °C, the reaction mixture is cooled to room temperature, and the completion of the reaction is checked by TLC (Note 12). The mixture is filtered through a short pad of silica gel (inner diameter = 10 cm, height of silica gel = 1 cm) (Note 13) and eluted with ethyl acetate (3 × 50 mL) into 1 L round-bottomed flask (Note 14) (Figure 3A, 3B). The resulting solution is concentrated by rotary evaporation under reduced pressure (20 mmHg, 37 °C) to afford the crude product as a dark red oil (6.39 g) (Figure 3C).

Figure 2. Color change of the reaction mixture over the course of the reaction; (A) Before heating; (B) After 15 minutes; (C) After 24 hours (photos provided by checkers)

The crude oil is dissolved in dichloromethane (Note 15) and loaded on a flash column chromatography on silica gel (125 g, 5 cm column diameter) (Notes 13 and 16) using ethyl acetate (Note 14) and hexane (Note 17) as eluents. The desired product is obtained in fractions 12-16 (Note 16), which are combined and concentrated by rotary evaporation under reduced pressure (30 mmHg, 37 °C) to afford a yellow solid. The solid is then placed under a high vacuum (2 mmHg, 24 °C) for 70 min to afford 2.73 g (13.4 mmol, 67.0%) of 2-(4-acetylphenyl)cyclopentan-1-one (4) as a yellow solid (Notes 18, 19, and 20) (Figure 3D).

Figure 3. (A) Filtering through a short pad of silica gel; (B) The eluent after filtration; (C) The crude dark red oil; (D) Purified title compound 4 (photos provided by checkers)

2. Notes

1. Prior to performing each reaction, a thorough hazard analysis and risk assessment should be carried out with regard to each chemical substance and experimental operation on the scale planned and in the context of the laboratory where the procedures will be carried out. Guidelines for carrying out risk assessments and for analyzing the hazards associated with chemicals can be found in references such as Chapter 4 of "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at

https://www.nap.edu/catalog/12654/prudent-practices-in-the-laboratory-handling-and-management-of-chemical. See also "Identifying and Evaluating Hazards in Research Laboratories" (American Chemical Society, 2015) which is available via the associated website "Hazard Assessment in Research Laboratories" at

https://www.acs.org/content/acs/en/about/governance/committees/chemicalsafety/hazard-assessment.html. In the case of this procedure, the risk assessment should include (but not necessarily be limited to) an evaluation of the potential hazards associated with

cyclopentanone,

4'-bromoacetophenone,

palladium (II) acetate,

tri(o-tolyl)phosphine,

sodium acetate,

pyrrolidine,

1,1,3,3-tetramethylbutylamine,

1,4-dioxane,

hexane,

ethyl acetate,

dichloromethane and silica gel.

2. The heavy wall pressure vessel was purchased from ACE GLASS Co., Inc. and was oven-dried at 120 °C for 1 h and cooled to room temperature before use (checkers).

3.

Cyclopentanone (≥99%) was purchased from Sigma-Aldrich and used as received.

4.

4'-Bromoacetophenone (99%) was purchased from Oakwood Chemical and used as received (submitters).

4'-Bromoacetophenone (>98%) was purchased from Tokyo Chemical Industry Co., Ltd. and used as received (checkers).

5.

Palladium (II) acetate (98%) was purchased from Sigma-Aldrich and used as received.

6.

Tri(o-tolyl)phosphine (97%) was purchased from Sigma-Aldrich and used as received.

7.

Sodium acetate (anhydrous, 99%) was purchased from EM Science and used as received (submitters).

Sodium acetate (anhydrous, 99%) was purchased from Thermo Fisher Scientific Co., Inc. and used as received (checkers).

8.

Pyrrolidine (99%) was purchased from Sigma-Aldrich and distilled before use (submitters).

Pyrrolidine (99%) was purchased from Sigma-Aldrich and distilled with calcium hydride at 92 °C before use (checkers).

9.

1,1,3,3-Tetramethylbutylamine (98%) was purchased from TCI Chemical and used as received.

10.

1,4-Dioxane (HPLC grade, 99.5%) was purchased from Sigma-Aldrich and distilled from sodium-benzophenone ketyl (submitters).

1,4-Dioxane (anhydrous, 99.8%) was purchased from Sigma-Aldrich and used as received (Checkers).

11. The reaction can also be conducted using a glovebox following the procedure described below. (This experimental protocol was provided by the submitters, but not confirmed by the checkers.) A 350 mL heavy-walled pressure vessel, equipped with a Teflon-coated oval magnetic stirring bar (30 mm × 10 mm) is charged with

cyclopentanone (1.68 g, 20.0 mmol, 1 equiv) (

Note 3),

4'-bromoacetophenone (5.18 g, 26.0 mmol, 1.3 equiv) (

Note 4),

palladium(II) acetate (45 mg, 0.20 mmol, 1 mol%) (

Note 5),

tri(o-tolyl)phosphine (122 mg, 0.40 mmol, 2 mol%) (

Note 6),

sodium acetate (1.64 g, 20.0 mmol, 1 equiv) (

Note 7),

pyrrolidine (0.50 mL, 6.0 mmol, 30 mol%) (

Note 8) and

1,1,3,3-tetramethylbutylamine (0.96 mL, 6.0 mmol, 30 mol%) (

Note 9). The vessel is then gently blown with nitrogen gas for 30 sec, capped with a Teflon bushing, and transferred into a glove box under nitrogen. In the glove box, the vessel is uncapped and charged with

1,4-dioxane (100 mL) (

Note 10) via a syringe. The reaction mixture is stirred (400 rpm) for 5 min at room temperature in the glove box. The reaction vessel is then capped with the Teflon bushing and transferred out of the glove box. A blast shield is placed in front of the closed vessel. After stirring (600 rpm) for 24 h at 130 °C, which is the temperature of an oil bath, the reaction mixture is cooled to room temperature. The rest of the procedure follows the standard one shown in the main text.

12. The reaction progress was monitored by TLC analysis,

hexane/

ethyl acetate (2/1, v/v), R

f (product) = 0.29.

Figure 4. Thin-layer chromatography (TLC) analysis of the reaction mixture; (A) Visualized by 254 nm UV. Left-to-right: The starting materials (compounds 1 and 2) ; Co-spot of starting materials and the reaction mixture; The reaction mixture; (B) Visualized by anisaldehyde stain. Left-to-right: The starting materials (compounds 1 and 2); Co-spot of starting materials and the reaction mixture; The reaction mixture (photos provided by checkers)

13. Silica gel (60 N, 0.040-0.050 mm, spherical and neutral) was obtained from Kanto Chemical Co., Inc. and was used as received.

14.

Ethyl acetate (99.5%) was purchased from Fisher Chemical (submitters).

Ethyl acetate (>99.3%) was purchased from Kanto Chemical Co., Inc. and used as received (checkers).

15.

Dichloromethane (99.5%) was purchased from Fisher Chemical (submitters).

Dichloromethane (>99.5%) was purchased from Kanto Chemical Co., Inc. and used as received (checkers).

16. Column chromatography was performed as follows: A flash column (5 cm diameter) is charged with sea sand to a height of 1 cm and then with silica gel (125 g) using a wet-pack method with

hexane (400 mL) to give a column height of 13 cm. Sea sand with a 1 cm minimum height is added to the top of the column. The crude oil is loaded onto the column using 13 mL of

dichloromethane (

Note 18). At this point, fraction collection (250 mL x 21) is begun, and elution is continued with 1 L of

hexane/

ethyl acetate (10/1, v/v), then 1 L of

hexane/

ethyl acetate (8/1, v/v), then 3.25 L of

hexane/

ethyl acetate (4/1, v/v) using compressed air.

Figure 5. TLC analysis of column chromatography (A) Visualized by 254 nm UV; (B) Visualized by anisaldehyde stain (photos provided by checkers)

17.

Hexane (98.5%) was purchased from Fisher Chemical (submitters).

Hexane (>96.0%) was purchased from Kanto Chemical Co., Inc. and used as received (checkers).

18. Characterization data of product

4:

1H NMR

pdf (400 MHz, CDCl

3) δ: 7.93 (d,

J = 8.2 Hz, 2H), 7.29 (d,

J = 8.2 Hz, 2H), 3.40 (dd,

J = 11.9, 8.7 Hz, 1H), 2.59 (s, 3H), 2.57 - 2.45 (m, 2H), 2.32 (m, 1H), 2.24 - 2.09 (m, 2H), 1.98 (m, 1H).

13C NMR

pdf (100 MHz, CDCl

3) δ: 216.9, 197.7, 143.8, 135.8, 128.6, 128.4, 55.3, 38.3, 31.4, 26.6, 20.8. IR (KBr film): 2965, 2878, 1732, 1683, 1606, 1416, 1361, 1269 cm

-1. HRMS (ESI+). m/z calcd for C

13H

14NaO

2+ [M+Na]

+: 225.0886; found 225.0897. Melting point: 79.0 - 79.8 °C. The product (

4) is stable on the benchtop at room temperature under air atmosphere.

19. The purity of product (

4) was determined to be 98.5% by quantitative

1H NMR

pdf spectroscopy in CDCl

3 using 15.5 mg of the product (

4) and 12.9 mg of

1,3,5-trimethoxybenzene (FUJIFILM Wako Pure Chemical Corporation, ≥99.0%, used as received) as an internal standard.

20. A second reaction on identical scale provided 2.84 g (70%) of the same product.

Working with Hazardous Chemicals

The procedures in

Organic Syntheses are intended for use only by persons with proper training in experimental organic chemistry. All hazardous materials should be handled using the standard procedures for work with chemicals described in references such as "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at

http://www.nap.edu/catalog.php?record_id=12654). All chemical waste should be disposed of in accordance with local regulations. For general guidelines for the management of chemical waste, see Chapter 8 of Prudent Practices.

In some articles in Organic Syntheses, chemical-specific hazards are highlighted in red "Caution Notes" within a procedure. It is important to recognize that the absence of a caution note does not imply that no significant hazards are associated with the chemicals involved in that procedure. Prior to performing a reaction, a thorough risk assessment should be carried out that includes a review of the potential hazards associated with each chemical and experimental operation on the scale that is planned for the procedure. Guidelines for carrying out a risk assessment and for analyzing the hazards associated with chemicals can be found in Chapter 4 of Prudent Practices.

The procedures described in Organic Syntheses are provided as published and are conducted at one's own risk. Organic Syntheses, Inc., its Editors, and its Board of Directors do not warrant or guarantee the safety of individuals using these procedures and hereby disclaim any liability for any injuries or damages claimed to have resulted from or related in any way to the procedures herein.

3. Discussion

Ketone moieties not only commonly exist in various functional organic molecules, but also routinely serve as handles to install other functional groups.

2 Thus, efficient and site-selective ketone functionalization methods play an important role in modern organic synthesis.

3 Among various ketone functionalization strategies, the Buchwald-Hartwig-Miura (BHM) arylation has been a widely used approach for α-arylation of ketones via transition metal-catalyzed cross-couplings with aryl halides.

4 However, simple or less substituted cyclopentanones have been very difficult substrates for the BHM reaction, attributed to the side reaction of cyclopentanones under strong basic conditions.

5 To address the challenge of α-arylation of cyclopentanones, a new strategy based on the palladium/enamine cooperative catalysis was developed by our group in 2016.

6 High selectivity of monoarylation, exceptional chemoselectivity, as well as broad functional-group tolerance, were achieved with this method. The secondary amine employed in this reaction was proposed to play a key role in both reactivity and selectivity, since it can (i) avoid side reactions of cyclopentanones due to its low basicity, and (ii) avoid multi-arylations due to that enamine formation is sensitive to steric of the ketone substrates.

This reaction shows a broad substrate scope (Table 1). Substitutions at the para-, meta- and ortho-positions of aryl halides, as well as many sensitive functional groups, such as aryl chloride, fluoride, esters, nitriles, amides, thioethers, and tocopherol moieties, were tolerated. In addition, acidic or electrophilic functional groups, aryl silanes, and boronic esters were compatible. In addition, various cyclopentanones with different substation patterns were suitable for this reaction. Good site-selectivity was observed with the α-substituted cyclopentanones, favoring arylation at the less sterically hindered side. Therefore, this reaction could represent a general method for mono-α-arylation of cyclopentanones.

The reaction works well on a gram-scale, as shown in this report. Typically, 1 mol% of palladium loading is sufficient on a gram-scale, but higher catalyst loading, higher reaction temperature, and longer reaction time generally help to increase the conversion of this reaction. Some products in the scope table have weak UV absorption, which can hinder analysis of the reaction by TLC. In these cases, use of phosphomolybdic acid (PMA) stain is recommended.

Table 1. Selected Substrate Scope

Yields shown are those of the isolated product. The d.r. and r.r. values were determined by NMR analysis of the crude reaction mixture. (a) With 10 mol% Pd(OAc)2, 20 mol% P(o-tol)3; (b) 24 h; (c) With 2 equiv of ArBr, 18 h; (d) With 10 mol% Pd(OAc)2, 20 mol% P(o-tol)3 and 50 mol% of pyrrolidine; (e) Without 1,1,3,3-tetramethylbutylamine, 24 h; (f) 18 h. pin = pinacol. Ts = 4-toluenesulfonyl.

Appendix

Chemical Abstracts Nomenclature (Registry Number)

Cyclopentanone; (1) (120-92-3)

4'-Bromoacetophenone; (2) (99-90-1)

Palladium(II) acetate; (3375-31-3)

Tri(o-tolyl)phosphine; (6163-58-2)

Sodium acetate; (127-09-3)

Pyrrolidine; (123-75-1)

1,1,3,3-Tetramethylbutylamine; (107-45-9)

|

Yibin Xue was born in Xi'an of Shaanxi Province in China in 1995. He received a B.S. degree in chemistry from Peking University in 2017. He then moved to the University of Chicago to begin his graduate studies under the supervision of Professor Guangbin Dong at the University of Chicago. His research focuses on the total synthesis of natural products through "cut-and-sew" reactions and C-C activation of unstrained C-C bonds. |

|

Arjuna Parsad was born in Chicago's south side in 2003. He is a sophomore at Tulane University, where is working towards a B.S. in Chemistry. He works as an intern student in the Dong group under the mentoring of Yibin Xue. His current work focuses on C-C activation of unstrained C-C bonds. |

|

Guangbin Dong was born in Qingdao of Shandong Province in China in 1981. He received his B.S. degree from Peking University in 2003 and completed his Ph.D. in Chemistry from Stanford University with Professor Barry M. Trost in 2009. After two years of postdoctoral training with Professor Robert H. Grubbs at California Institution of Technology, he joined the faculty of the University of Texas at Austin in 2011. In 2016, he moved to the University of Chicago as a Professor of Chemistry. His current research interests include transition-metal-catalyzed C-H and C-C bonds activation, total synthesis of bioactive natural products, boron chemistry, and development of new materials. |

|

Jaejoong Han was born in Tokyo, Japan. He graduated from the University of Tokyo in 2022 with B.S. in Pharmaceutical Science. He is continuing his graduate studies at the University of Tokyo under the supervision of Prof. Masayuki Inoue. His research interests are in the total synthesis of complex natural products. |

|

Masanori Nagatomo completed his Ph.D. (2012) at the University of Tokyo under the supervision of Professor Masayuki Inoue. In 2012, he carried out visiting research with Professor Phil S. Baran at The Scripps Research Institute. In the same year, he was appointed as Assistant Professor at the Graduate School of Pharmaceutical Sciences at the University of Tokyo and was promoted to Lecturer in 2018. His research efforts focus on the development of novel synthetic methodologies and applications for the multistep synthesis of complex molecules. |

Copyright © 1921-, Organic Syntheses, Inc. All Rights Reserved