Org. Synth. 2024, 101, 21-33

DOI: 10.15227/orgsyn.101.0021

Synthesis of Deuterated 1H-Indole-3-carboxaldehyde via Catalytic Vilsmeier-Haack Reaction

Submitted by Jing Xue, Yushan Zhang, Bing Zhong, and Jin-Dong Yang*

1Checked by Paolo Piacentini, Omar Abdo and Nuno Maulide

1. Procedure (Note 1)

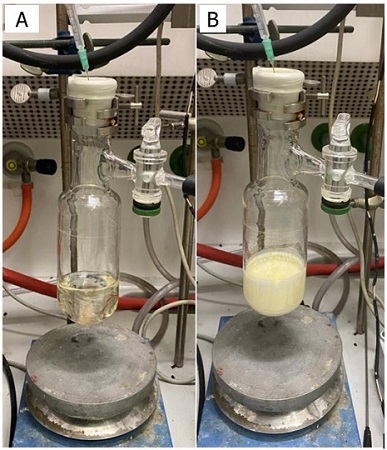

A flame-dried 200 mL Schlenk flask equipped with a 2.5 cm Teflon-coated magnetic stir bar and a rubber septum is maintained under an atmosphere of argon during the reaction. The flask is charged with indole (2.34 g, 20.0 mmol, 1.0 equiv) (Note 2) and 3-methyl-1-phenyl-2-phospholene 1-oxide (576 mg, 3.0 mmol, 0.15 equiv) (Note 3). The flask is evacuated and refilled with argon three times. Anhydrous acetonitrile (40 mL) (Note 4) is added by syringe to afford a light-yellow solution. Diethyl bromomalonate (DEBM) (4.10 mL, 24.0 mmol, 1.2 equiv) (Note 5), deuterated N,N-dimethylformamide (2.33 mL, 30.0 mmol, 1.5 equiv) (Note 6), and PhSiH3 (3.69 mL, 30.0 mmol, 1.5 equiv) (Note 7) are added by syringe in sequence. An argon-filled balloon is then attached to the system (Figure 1A). The resulting reaction mixture is stirred (600 rpm) at room temperature (Note 8) for 16 h. During the reaction, the solution gradually becomes cloudy (Figure 1B). 2 M NaOH (40 mL) (Note 9) is carefully added dropwise over 10-min to quench the reaction mixture to give a clear solution (Figure 2A). The resultant mixture is diluted with ethyl acetate (50 mL) (Note 10) and then transferred to a 250 mL separatory funnel. The organic phase layer is separated, and the aqueous is extracted with ethyl acetate (3 x 50 mL). The combined organic layers are then washed with brine (30 mL) (Note 11) and dried over anhydrous MgSO4 (7 g) for 10 min (Note 12). The solution is filtered through a bed of celite (~ 1 cm thick) (Note 13) in a 60 mL glass funnel and washed with ethyl acetate (3 x 15 mL) (Figure 2B). The filtrate is used to conduct TLC analysis (Figure 2C) (Note 14). The filtrate is then concentrated to about 15 mL by rotary evaporation (45 ℃, 120 mmHg). The residue is redissolved in acetone (30 mL) (Note 15) and transferred to a 100 mL round-bottomed flask. The solvent is removed by rotary evaporation (45 ℃, 120 mmHg) to give the crude product as a yellow solid. Dichloromethane (5 mL) (Note 16) and a 1.5 cm Teflon-coated magnetic stir bar are added to the crude product, and the resulting mixture is stirred at 500 rpm for 30 min to produce a slurry (Figure 2D). The resulting mixture is filtered through filter paper on a 60 mL glass funnel under vacuum suction using a water aspirator (Figure 2E). The filter cake is washed with petroleum ether (15 mL x 3) (Note 17). The solid is transferred to a 100 mL round-bottomed flask and kept under a high vacuum (0.1 mmHg) at room temperature for 4 h to afford the pure product (2.20 g, 75%) as a pale-yellow solid (Notes 18, 19, and 20) (Figure 2F).

Figure 1. A) Reaction set-up; B) Reaction solution after 16 h (photos provided by checkers)

Figure 2. A) Appearance after addition of aqueous NaOH; B) Filtrate of Celite filtration; C) TLC analysis; D) Slurry; E) Filtration of the slurry; F) Pure product (photos provided by authors)

2. Notes

1. Prior to performing each reaction, a thorough hazard analysis and risk assessment should be carried out with regard to each chemical substance and experimental operation on the scale planned and in the context of the laboratory where the procedures will be carried out. Guidelines for carrying out risk assessments and for analyzing the hazards associated with chemicals can be found in references such as Chapter 4 of "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at

https://www.nap.edu/catalog/12654/prudent-practices-in-the-laboratory-handling-and-management-of-chemical. See also "Identifying and Evaluating Hazards in Research Laboratories" (American Chemical Society, 2015) which is available via the associated website "Hazard Assessment in Research Laboratories" at

https://www.acs.org/content/acs/en/about/governance/committees/chemicalsafety/hazard-assessment.html. In the case of this procedure, the risk assessment should include (but not necessarily be limited to) an evaluation of the potential hazards associated with

indole,

3-methyl-1-phenyl-2-phospholene 1-oxide,

diethyl bromomalonate,

phenylsilane, deuterated

N,N-dimethylformamide,

acetonitrile,

NaOH,

ethyl acetate,

petroleum ether,

Celite, anhydrous

MgSO4 and deuterated

DMSO.2. The authors purchased

indole (>99.8%) from Bide pharmatech Co., Ltd and used it as received. The checkers purchased

indole (≥99%) from Sigma-Aldrich and used it as received.

3. The authors purchased

3-methyl-1-phenyl-2-phospholene 1-oxide (>97%) from Bide pharmatech Co., Ltd. and used as received. The checkers purchased

3-methyl-1-phenyl-2-phospholene 1-oxide (97%) from BLDpharm and used it as received.

4. The authors purchased anhydrous

acetonitrile (

H2O < 50 ppm) from J&K Scientific and used it as received. The checkers purchased anhydrous

acetonitrile (

H2O < 50 ppm) from Acros and used it as received.

5. The authors purchased

diethyl bromomalonate (>97%) from Innochem and used it as received. The checkers purchased

diethyl bromomalonate (98%) from BLDpharm and used it as received.

6. The authors purchased deuterated

N,N-dimethylformamide (>99.5% D) from TCI and used it as received. The checkers purchased

N,N‐dimethylformamide (≥99.5% D) from Sigma-Aldrich and used it as received.

7. The authors purchased

PhSiH3 (>97%) from Innochem and used it as received. The checkers purchased

PhSiH3 (>96%) from TCI and used it as received.

8. The term "room temperature" used throughout this manuscript refers to a temperature between 20 to 25 ℃.

9.

Sodium hydroxide (

NaOH) was purchased from General-Reagent and used as received. The

NaOH solution (2 M) was prepared using

NaOH and deionized water.

10.

Ethyl acetate was purchased from General-Reagent and used as received.

11.

Sodium chloride (

NaCl) was purchased from General-Reagent. The brine solution was prepared using

NaCl and deionized water.

12. Anhydrous

MgSO4 was purchased from General-Reagent and used as received.

13. The authors purchased

Celite from Bide pharmatech Co., Ltd. and used it as received. The checkers purchased

Celite from Sigma-Aldrich and used it as received.

14. The authors performed TLC analysis (TLC silica gel 60 F253, precoated plates (0.25 mm) purchased from Shanghai Haohong Scientific Co., Ltd) of the mixture with

petroleum ether/

ethyl acetate (2:1) as the eluent. The desired product is the third spot from the top on the silica gel plate. The R

f of the product = 0.2, and the R

f of the starting material = 0.8 (Figure 2C). The checkers performed TLC analysis (TLC silica gel 60 purchased from Merck KGaA) of the mixture with

petroleum ether/

ethyl acetate (2:1) as the eluent is shown below. The R

f of the product = 0.1, and the R

f of the starting material = 0.8.

15.

Acetone was purchased from General-Reagent and used as received.

16.

Dichloromethane was purchased from General-Reagent and used as received.

17.

Petroleum ether was purchased from General-Reagent and used as received.

18.

1H-Indole-3-carboxaldehyde-formyl-d1 (

2):

1H NMR (600 MHz,

DMSO-d6)

1H NMR

pdf (600 MHz,

DMSO) δ: 8.27 (s, 1H), 8.09 (d,

J = 7.7 Hz, 1H), 7.51 (d,

J = 8.0 Hz, 1H), 7.28 - 7.24 (m, 1H), 7.24 - 7.20 (m, 1H).

13C NMR

pdf (151 MHz,

DMSO) δ: 184.9, 138.6, 137.2, 124.2, 123.6, 122.2, 120.9, 118.2, 112.5. IR (neat): 3380, 2989, 2915, 1638, 1043, 921 cm

-1. mp = 198-200 ℃; HRMS (ESI)

m/z calc. for C

9H

7DNO

+ (M+H)

+: 147.0663, found 147.0660.

19. The purity and deuterium incorporation of compound

2 was determined by quantitative

1H NMR

pdf analysis with a relaxation delay of 20 sec using 3.9 mg of compound

2 and 4.5 mg of

1,3,5-trimethoxybenzene (purity >98%) as the internal standard. The purity of the compound

2 is >98%.

20. A repeated reaction on half scale afforded the product in 77% yield (1.12 g) with a purity of >98%.

Working with Hazardous Chemicals

The procedures in

Organic Syntheses are intended for use only by persons with proper training in experimental organic chemistry. All hazardous materials should be handled using the standard procedures for work with chemicals described in references such as "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at

http://www.nap.edu/catalog.php?record_id=12654). All chemical waste should be disposed of in accordance with local regulations. For general guidelines for the management of chemical waste, see Chapter 8 of Prudent Practices.

In some articles in Organic Syntheses, chemical-specific hazards are highlighted in red "Caution Notes" within a procedure. It is important to recognize that the absence of a caution note does not imply that no significant hazards are associated with the chemicals involved in that procedure. Prior to performing a reaction, a thorough risk assessment should be carried out that includes a review of the potential hazards associated with each chemical and experimental operation on the scale that is planned for the procedure. Guidelines for carrying out a risk assessment and for analyzing the hazards associated with chemicals can be found in Chapter 4 of Prudent Practices.

The procedures described in Organic Syntheses are provided as published and are conducted at one's own risk. Organic Syntheses, Inc., its Editors, and its Board of Directors do not warrant or guarantee the safety of individuals using these procedures and hereby disclaim any liability for any injuries or damages claimed to have resulted from or related in any way to the procedures herein.

3. Discussion

The Vilsmeier-Haack reaction is a classic method to directly install formyl groups to electron-rich aromatic rings.

2 However, the tedious approach and the use of stoichiometric hazard POCl

3 limits its application.

3 We envisaged that a halo-phosphonium (V) ion

4 may serve as a surrogate for POCl

3 to render a catalytic version of the Vilsmeier-Haack reaction. In recent years, the catalytic version of several widely used name reactions, such as Wittig,

5 Appel,

6 Mitsunobu,

7 and Cadogan reactions

8 have been developed via P(III)/P(V)=O cycles. Very recently, our group reported a new catalytic version of the Vilsmeier-Haack-type formylation of indoles enabled by P(III)/P(V)=O cycle.

9 Deuterated indole-3-carboxaldehydes were obtained when stoichiometric DMF-d7 was employed as the deuterium source. The reaction conditions are mild for late-stage formylation.

Ester (2c), nitrile (2d), acetyl (2e), and even (pinacolato)boryl (2f) groups were well-tolerated, as shown in Scheme 1. This approach is also applicable in late-stage formylation. Indoles derived from pharmaceuticals and natural products, such as probenecid (2g), naproxen (2h), and paroxetine (2i) could undergo formylation to give deuterated products in good yields. Moreover, it is accessible to other carbonyl compounds from amides (other than DMF) via this reaction (2j-2n). A higher temperature (60 ℃) was required to furnish these products in moderate to good yields.

Scheme 1. Substrate scope. Reaction conditions: indole (0.5 mmol), amide (1.3 equiv), 3-methyl-1-phenyl-2-phospholene 1-oxide (0.15 equiv), DEBM (1.2 equiv), and PhSiH3 (1.5 equiv) in MeCN (2 mL) at room temperature

Deuterated indole-3-carboxaldehydes are useful deuterium building blocks. Several deuterated products were obtained in the downstream transformation of indole-3-carboxaldehyde with excellent deuterium abundance (Scheme 2), which manifested their potential application in synthesis of deuterated bioactive molecules.

Scheme 2. Downstream transformation of the deuterated indole-3-carboxaldehyde

Appendix

Chemical Abstracts Nomenclature (Registry Number)

Indole; (120-72-9)

3-Methyl-1-phenyl-2-phospholene 1-oxide; (707-61-9)

Dimethylformamide-D7; (4472-41-7)

Diethyl bromomalonate; (685-87-0)

Phenylsilane; (694-53-1)

|

Jing Xue was born in Anhui, China, in 1995. He received his Bachelor's degree from Nankai university in 2018. He is currently a doctoral student under the supervision of Professor Jin-Pei Cheng in the Department of Chemistry, Tsinghua University. His research interests focus on catalyst design and mechanistic studies in organo-phosphorous catalysis. |

|

Yushan Zhang was born in Beijing, China, in 2000. She graduated from Beijing Normal University in 2021. She is currently a Ph.D. candidate working in Cheng's group in the Department of Chemistry of Tsinghua University. Her current interests focus on the thermodynamics of organic compounds. |

|

Bing Zhong received his Bachelor's degree in Chemistry from Central China Normal University in 2022. He is currently pursuing his Ph.D. in Cheng's Group in the Department of Chemistry at Tsinghua University. His current research focuses on organophosphorus compounds. |

|

Jin-Dong Yang graduated from Nankai University (2009). He received his Ph.D. degree from Nankai University (2014). Then, he became a postdoctoral fellow in the same campus with Prof. Jin-Pei Cheng. In 2017, he joined Center of Basic Molecular Science (CBMS) in Tsinghua University. His current research focuses on physical organic chemistry of organophosphorus compounds as well as their synthetic applications. |

|

Omar Abdo was born in Aleppo, Syria in 1989. He studied chemistry at the University of Aleppo for four years, then continued his education in Austria at the Higher federal teaching and research institute for chemical industry, graduating in 2020. Currently, he works at the University of Vienna as a laboratory technician in the Prof. Nuno Maulide's group since 2020. |

|

Paolo Piacentini was born in Alessandria, Italy, in 1995. He received his Ph.D. degree in 2023 from Pavia University under the supervision of Prof. David Sarlah. Currently, he is a postdoctoral fellow at Vienna University in Prof. Nuno Maulide's group. His research focuses on entropy-oriented drug design. |

Copyright © 1921-, Organic Syntheses, Inc. All Rights Reserved