Org. Synth. 2024, 101, 258-273

DOI: 10.15227/orgsyn.101.0258

One-pot Synthesis of Alkynes from Esters via a Tandem Reduction-Ohira-Bestmann Reaction

Submitted by Cholapat Varongchayakul and Rick L. Danheiser*

1Checked by Hojoon Park and Kevin R. Campos

1. Procedure (Note 1)

tert-Butyl (R)-2-ethynylpyrrolidine-1-carboxylate (2). A 500-mL, three-necked, round-bottomed flask is equipped with an N2 inlet adapter, a 125-mL pressure-equalizing addition funnel fitted with a rubber septum, a rubber septum with an internal temperature probe, and a 32 x 15.9 mm Teflon-coated egg-shaped magnetic stir bar (Figure 1) (Note 2). A solution of N-Boc-D-proline methyl ester (4.00 g, 17.4 mmol, 1.0 equiv) (Note 3) in 10 mL of dichloromethane (Note 4) is prepared in a 20-dram vial under N2 and transferred into the reaction flask via syringe. The vial is rinsed with dichloromethane (10 mL) and the liquid transferred into the reaction flask. Additional dichloromethane (20 mL) is added, and the reaction mixture is cooled to -76 ℃ (internal temperature) in a dry ice-acetone bath. A solution of DIBAL-H (1M in hexanes, 34.9 mL, 34.9 mmol, 2.0 equiv) (Note 5) is transferred via syringe into the addition funnel.

Figure 1. (A) N-Boc-D-proline methyl ester weighed in 20 ml vial; (B) Reaction assembly; (C) Reaction mixture before DIBAL-H addition (photos provided by checkers)

The DIBAL-H solution is added dropwise over 30 min at a rate that maintains the temperature of the reaction mixture below -70 ℃ (Figure 2). Hexanes (5 mL) (Note 6) is added via the addition funnel to the clear, colorless reaction mixture, which is then allowed to stir at -76 ℃ (Note 7). After 2.5 h, anhydrous methanol (40 mL) (Note 8) is added dropwise over 5 min via the addition funnel at a rate that maintains the temperature below -50 ℃. Effervescence is observed during the first 30 seconds of the addition (Figure 2B). The dry ice-acetone bath is then replaced with an ice-water bath, and the reaction mixture is allowed to warm to 0 ℃ over a period of 5 min, and the solution is stirred at 0 ℃ for 5 min. Upon reaching 0 ℃, a thick slurry of white gel-like precipitate is formed (Figure 2C) (Notes 9 and 10).

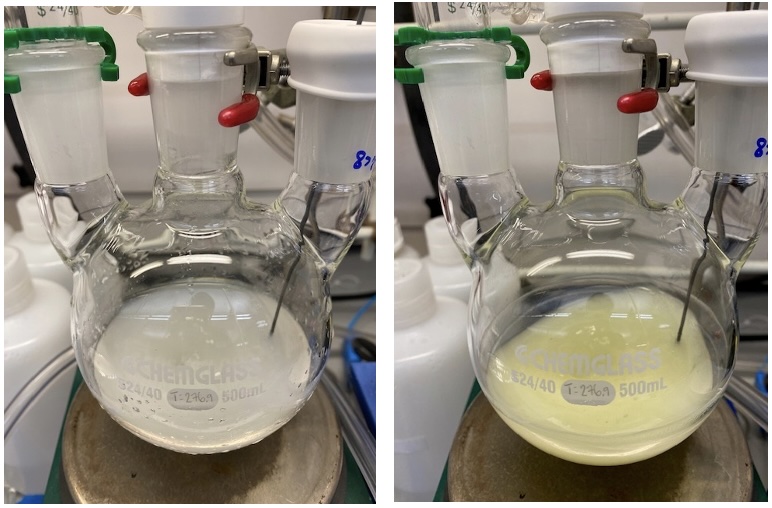

The addition funnel is removed from the flask, and potassium carbonate (4.82 g, 34.9 mmol, 2.0 equiv) (Note 11) is added in one portion via the open neck under a strong flow of N2. A new septum is immediately attached to the flask, and dimethyl (1-diazo-2-oxopropyl)phosphonate (3.14 mL, 20.9 mmol, 1.2 equiv) (Notes 12 and 13) is added rapidly (ca. 10 sec) via syringe. The ice-water bath is removed, and the cloudy reaction mixture is allowed to warm from 0 ℃ to 22 ℃ and then stirred at room temperature for 18 h over which time it becomes pale yellow in color (Figure 3).

Figure 2. Reaction mixture (A) after DIBAL-H addition; (B) Effervescence during methanol addition; (C) White precipitate at 0 ℃ (photos provided by checkers)

After 18 h, methyl t-butyl ether (100 mL) (Note 14), saturated aqueous Rochelle's salt (75 mL) (Note 15), and distilled water (50 mL) are added to the reaction mixture, which is then stirred at 22 ℃ for 1 h. At this point, the reaction mixture separates into two clear phases. This mixture is transferred into a 500-mL separatory funnel (Figure 4), and the aqueous layer is separated and extracted with methyl t-butyl ether (3 x 20 mL). The combined organic phases are washed with saturated sodium chloride solution (50 mL), dried for 5 min over anhydrous magnesium sulfate (5 g), and filtered under reduced pressure (20 mmHg) through a 60 mL plastic filter (10 micron). The MgSO4 is washed with methyl t-butyl ether (3 x 20 mL), and the filtrate is concentrated by rotary evaporation (23 ℃, 100 mmHg) (Note 16) to yield 5.4 g of a yellow oil (Figure 4C).

Figure 3. (A) Reaction mixture after addition of diazo keto-phosphonate reagent and warming to room temperature; (B) Reaction mixture after 18 h (photos provided by checkers)

Figure 4. (A) Partitioning of organic and aqueous phases; (B) Organic phase filtrate; (C) Crude reaction product after concentration (photos provided by checkers)

This material is loaded onto an automated column which contains 52 g of silica gel, equilibrated with hexanes (Note 17 and 18) (Figure 5). Elution is performed with a gradient from 100% hexanes to 8:1 hexanes/EtOAc, and fractions were collected in 18 x 160 mm test tubes (Notes 19 and 20). Fractions 17-24 contained the desired product (TLC conditions = 3:1 hexanes/EtOAc, KMnO4 stain, Rf = 0.63) (Note 21). Fractions are collected and concentrated in a 250 mL flask by rotary evaporation (23 ℃, 20 mmHg (Note 22) to yield 2.48 g (73%, 97.5% purity as determined by qNMR) of 2 as a colorless oil (Figure 5C) (Notes 23, 24, and 25).

Figure 5. (A) Column setup; (B) Chromatogram; (C) Final product (photos provided by checkers)

2. Notes

1. Prior to performing each reaction, a thorough hazard analysis and risk assessment should be carried out with regard to each chemical substance and experimental operation on the scale planned and in the context of the laboratory where the procedures will be carried out. Guidelines for carrying out risk assessments and for analyzing the hazards associated with chemicals can be found in references such as Chapter 4 of "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at

https://www.nap.edu/catalog/12654/prudent-practices-in-the-laboratory-handling-and-management-of-chemical. See also "Identifying and Evaluating Hazards in Research Laboratories" (American Chemical Society, 2015) which is available via the associated website "Hazard Assessment in Research Laboratories" at

https://www.acs.org/about/governance/committees/chemical-safety.html. In the case of this procedure, the risk assessment should include (but not necessarily be limited to) an evaluation of the potential hazards associated with

dichloromethane,

N-Boc-D-Proline methyl ester,

diethyl-(1-diazo-2-oxopropyl)phosphonate,

DIBAL-H, hexanes,

potassium carbonate,

methyl tert-butyl ether,

ethyl acetate, and silica gel.

2. The authors flame-dried the glassware under vacuum (0.1 mmHg). As open flames are now forbidden in many laboratories for safety reasons (especially in industry), the checkers instead dried the glassware using a heat gun under vacuum for 10 min, back-filled with

N2 while hot, and then maintained an inert atmosphere during the course of the reaction.

3.

N-Boc-D-proline methyl ester (95%) was purchased from Oakwood Chemicals and used as received.

4.

Dichloromethane was purified by pressure filtration under argon through activated alumina.

5.

DIBAL-H (1M in hexanes) was purchased from Sigma-Aldrich and used as received. The checkers transferred the solution using a combination of 24 mL and 1 mL syringes. The authors used a cannula to transfer the

DIBAL solution to a flame-dried graduated cylinder, from which the solution was transferred to the addition funnel by cannula.

6. Hexanes (mixture of isomers, >98.5%) was purchased from Sigma-Aldrich and used as received.

7. Monitoring the reduction by TLC analysis is difficult as the ester starting material and aldehyde product have the same Rf values with eluants such as 9:1 hexanes-

ethyl acetate, 4:1 hexanes-

ethyl acetate, and 9:1

dichloromethane-

ethyl acetate.

8.

Methanol (anhydrous, > 99%) was purchased from Mallinckrodt Chemicals and was dried and stored over 3A molecular sieves before use.

9. Upon reaching -14 ℃, the heterogeneous reaction mixture becomes a clear homogeneous solution, which turns back into a slurry while stirring at 0 ℃. (Figure 6)

Figure 6. (A) Reaction mixture immediately after placing into an ice bath; (B) Reaction mixture becomes homogeneous solution when internal temperature reached -14 ℃; (C) Reaction mixture turns back into heterogeneous slurry while stirring at 0 ℃ (photos provided by checkers)

10. If stirring is not strong enough, the solution may turn into a gel that prevents stirring. The gel can be broken up using a metal spatula (Figure 7), and after dilution with 30 mL of hexanes stirring can be resumed.

Figure 7. Reaction mixture turned into a gel after warming to 0 ℃ when stirring is insufficient. (A) Mixture side view; (B) Mixture top view; (C) Mixture after mechanically broken up using a metal spatula (photos provided by authors)

11.

Potassium carbonate (anhydrous, > 98%) was purchased from Alfa Aesar and used as received.

12.

Dimethyl (1-diazo-2-oxopropyl)phosphonate (> 97%), used by the checkers, was purchased from Chem-Impex and purified by column chromatography.

13.

Dimethyl (1-diazo-2-oxopropyl)phosphonate, used by the authors, was prepared by the procedure described in

Organic Syntheses.2 This reagent is also available commercially.

14.

Methyl t-butyl ether (ACS Reagent, > 99%) was purchased from Sigma-Aldrich and used as received.

15. Rochelle's Salt (sodium potassium tartrate) was purchased from Oakwood Chemicals and used as received.

16. Control of the rotary evaporation conditions is important to minimize product loss.

17. Silica gel (VWR "Industrial Grade" irregular silica gel 60A, 40-60 μm, 200-300 mesh) was used as received.

18. The column purification consists of two parts: a loading column (12 g of silica) where the material is directly loaded as oil, and the main column (40 g of silica) (Figure 5a). The entire 52 g of silica was equilibrated with hexanes prior to material loading.

19. A total 600 mL of solvent was used.

20. The authors purified the material through manual column chromatography by loading the oil onto a 60-mm diameter column packed with 50 g of silica gel (

Note 17), prepared as a slurry in 9:1 hexanes-

ethyl acetate. Elution is performed with 9:1 hexanes-

ethyl acetate and 20-mL fractions are collected in 18 x 160 mm test tubes with monitoring by TLC (

Note 21). The product is collected in fractions 7-19, which are combined in a 1-L round-bottomed flask and concentrated by rotary evaporation (23 ℃, 20 mmHg (

Note 22) to provide

2 as a colorless to pale yellow oil in similar yield to that which was reported by the checkers.

21. The TLC fractions were visualized using

KMnO4 stain (Figure 8) (1.5 g

KMnO4, 10 g

K2CO3, 1.25 mL 10% w/v

NaOH in 200 mL water) since none of the compounds are UV-active.

Figure 8. (A) TLC of combined organic phase (left) and combined aqueous phase (right); (B) Visualization of fractions (photos provided by checkers)

22. Concentration on the rotary evaporator at 20 mmHg is continued for no more than 1 h after the bulk of solvent has been removed. Drying at higher vacuum or for extended time leads to diminished yields due to loss of the volatile product.

23.

t-Butyl (R)-2-ethynylpyrrolidine-1-carboxylate (

2) has the following physical and spectroscopic properties: R

f = 0.24 (9:1 hexanes-

ethyl acetate; silica,

KMnO4); [α]

D20 +100.2 (c = 0.012, MeOH) (authors) and [α]

Hg54620 +140.1 (c = 0.012, MeOH) (checkers);

1H NMR

pdf (600 MHz, CDCl

3, mixture of rotamers) δ: 4.23-4.64 (m, 1H), 3.14-3.55 (m, 2H), 2.14-2.29 (m, 1H), 2.13-1.95 (m, 3H), 1.82-1.94 (m, 1H), 1.46 (s, 9H);

13C NMR

pdf (151 MHz, CDCl

3, mixture of rotamers) δ: 154.16, 84.6/84.3, 79.9, 69.9/69.5, 48.1/47.9, 46.1/45.6, 33.8/33.1, 28.6, 24.5/23.7 (rotameric peaks are grouped with /); FTIR (neat) : 3290, 3245, 2976, 2932, 2878, 1689, 1477, 1455, 1386, 1365, 1254, 1160, 1118, 1090, 1032, 977, 937, 913, 867, 770, 644, 577, 509, 451 cm

-1.

24. The purity of the product

2 was determined by qNMR

pdf analysis, which was performed by using trimethoxybenzene (ReagentPlus

®, ≥99%) purchased from Sigma-Aldrich as an internal standard.

25. A second reaction on identical scale provided 2.60 g (77%) of the same product with a purity of 97%.

Working with Hazardous Chemicals

The procedures in

Organic Syntheses are intended for use only by persons with proper training in experimental organic chemistry. All hazardous materials should be handled using the standard procedures for work with chemicals described in references such as "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at

http://www.nap.edu/catalog.php?record_id=12654). All chemical waste should be disposed of in accordance with local regulations. For general guidelines for the management of chemical waste, see Chapter 8 of Prudent Practices.

In some articles in Organic Syntheses, chemical-specific hazards are highlighted in red "Caution Notes" within a procedure. It is important to recognize that the absence of a caution note does not imply that no significant hazards are associated with the chemicals involved in that procedure. Prior to performing a reaction, a thorough risk assessment should be carried out that includes a review of the potential hazards associated with each chemical and experimental operation on the scale that is planned for the procedure. Guidelines for carrying out a risk assessment and for analyzing the hazards associated with chemicals can be found in Chapter 4 of Prudent Practices.

The procedures described in Organic Syntheses are provided as published and are conducted at one's own risk. Organic Syntheses, Inc., its Editors, and its Board of Directors do not warrant or guarantee the safety of individuals using these procedures and hereby disclaim any liability for any injuries or damages claimed to have resulted from or related in any way to the procedures herein.

3. Discussion

Terminal alkynes function as versatile building blocks for organic synthesis and a variety of methods have been developed for the preparation of these important synthons. The one-carbon homologation of aldehydes (Figure 1) serves as a particularly popular approach, and several recent reviews summarize methods for achieving this transformation.

3Scheme 1. One-carbon homologation of aldehydes

The Corey-Fuchs strategy, introduced in 1972,

4 continues to receive wide attention as a reliable method for effecting this homologation. Based on an olefination method introduced by Ramirez,

5 the Corey-Fuchs strategy proceeds via the generation of 1,2-dibromo alkenes that are treated with

n-butyllithium to produce alkynyllithiums that can be elaborated in situ by reaction with a variety of electrophilic reagents.

Another valuable strategy for the synthesis of alkynes from aldehydes involves the application of diazomethylphosphonate (DAMP) reagents (

5), also known as "Seyferth reagent".

6 Colvin first demonstrated the use of DAMP to effect the elaboration of aldehydes to homologous alkynes in 1973,

7 and Gilbert

8 subsequently introduced improvements that significantly expanded the scope of the method. In the Gilbert protocol, reaction of the aldehyde and DAMP takes place in the presence of potassium

t-butoxide at -78 ℃ and this version of the reaction can be applied to homologation of enolizable aldehydes and relatively unreactive compounds.

Scheme 2. Diazomethylphosphonate (Seyferth) DAMP reagents

The finding by Ohira in 1989 that the conjugate base of DAMP could be generated in situ from dialkyl (1-diazo-2-oxopropyl)phosphonates (

6) and used for aldehyde homologation represented a major advance in this area.

9 DAMP has a limited shelf life and requires a relatively lengthy synthesis whereas

6 is commercially available, can be stored indefinitely, and is easily prepared by diazo transfer beginning with commercially available keto phosphonates.

2Only a single example of aldehyde homologation was reported in Ohira's original paper, but subsequently Bestmann carried out a systematic investigation of the scope of the process that established optimal reaction conditions and demonstrated the wide generality of the method.

10,11 Attractive features of the "Ohira-Bestmann homologation" include:

- Wide scope with regard to aldehyde, including aryl, hetaryl, alkyl, and relatively sterically hindered substrates.

- Application to aldehydes with stereogenic centers at the α-carbon without loss of stereochemistry.

- Mild reaction conditions compatible with aldehydes that incorporate a wide range of functional groups.

One limitation, however, is that in general the method is not applicable to the synthesis of enynes from α,β-unsaturated aldehydes.

Scheme 3 outlines the mechanism of the Ohira-Bestmann reaction. Exposure of the "Ohira-Bestmann reagent"

6 to the action of potassium carbonate in methanol effects cleavage to generate the conjugate base of DAMP (

7). Reaction of

7 with aldehyde

3 leads to intermediate

8 that undergoes elimination to generate the diazo alkene

9. Loss of molecular nitrogen and 1,2-hydrogen shift then affords the terminal alkyne, most likely via an alkylidenecarbene intermediate. A number of variants of the Ohira-Bestmann protocol have been introduced,

12 and these are discussed in detail in a recent review.

13Scheme 3. Mechanism of the Ohira-Bestmann reaction

The instability and relatively limited shelf life of many aldehydes has stimulated the development of tandem strategies in which the aldehyde is generated in situ for the reaction from a more stable precursor. For example, Taylor introduced a strategy in which the requisite aldehyde is generated in situ by oxidation of an "activated" (e.g., benzylic) alcohol by oxidation with manganese dioxide.

14 In 2004, Hinkle and coworkers reported a more general strategy in which Weinreb amides and carboxylic esters serve as precursors to the aldehyde substrate via in situ reduction with DIBAL-H.

15In this

Organic Syntheses article we illustrate the Hinkle protocol through its application on a preparative scale to the synthesis of

N-Boc-2-ethynylpyrrolidine (

2) beginning from commercially available

N-Boc-D-proline methyl ester. 2-Substituted pyrrolidine derivatives derived from proline have shown considerable utility as synthetic building blocks,

16 and alkynylpyrrolidine

2 has been employed as an intermediate for the synthesis of pumiliotoxin 251D,

17 grandisine B and D

18, and various inhibitors of protozoan proliferation.

19As described in the above procedure section, ester 1 is first reduced using 2.0 equiv of DIBAL-H in DCM-hexane (ca. 0.2 M) at -78 ℃. Excess methanol is then added to quench remaining DIBAL, and the reaction mixture is allowed to warm to 0 ℃. Potassium carbonate (2 equiv) is then added followed immediately by 1.2 equiv of the Ohira-Bestmann reagent 6. The resulting mixture is allowed to warm to room temperature and stirred overnight prior to workup and purification.

The use of excess DIBAL was found to be essential as lower yields of the final alkyne were obtained when less reagent was employed. Whereas the final yield with 2 equiv of DIBAL was 74-76%, reaction with 1.0, 1.2, and 1.5 equivalents led to the formation of alkyne 2 in 0, 7, and 52% yield, respectively.

Appendix

Chemical Abstracts Nomenclature (Registry Number)

N-Boc D-proline methyl ester; (73323-65-6)

DIBAL-H: Diisobutylaluminum hydride; (1191-15-7)

Potassium carbonate; (584-08-7)

Diethyl (1-diazo-2-oxopropyl)phosphonate: Diethyl P-(1-diazo-2-oxopropyl)phosphonate; (21047-57-4)

Dimethyl (1-diazo-2-oxopropyl)phosphonate: Diemthyl P-(1-diazo-2-oxopropyl)phosphonate; (90965-06-3)

|

Cholapat Varongchayakul was born in Chonburi, Thailand in 2001. He is currently an undergraduate at the Massachusetts Institute of Technology and expects to receive his B.S. degree in chemistry in 2024. Cholapat joined the laboratory of professor Danheiser in 2020. |

|

Rick L. Danheiser received his undergraduate education at Columbia where he carried out research in the laboratory of Professor Gilbert Stork. He received his Ph.D. at Harvard in 1978 working under the direction of E. J. Corey on the total synthesis of gibberellic acid. Dr. Danheiser is the A. C. Cope Professor of Chemistry at MIT where his research focuses on the design and invention of new annulation and cycloaddition reactions, and their application in the total synthesis of biologically active compounds. |

|

Hojoon Park received his Ph.D. from The Scripps Research Institute in 2020 under the supervision of Prof. Jin-Quan Yu. During his time in the Yu lab, he worked on ligand development for palladium-catalyzed functionalization of aliphatic C-H bonds. After graduation, Hojoon joined Prof. Stephen L. Buchwald's laboratory at MIT as a postdoctoral researcher, where he continued his research in designing new ligands for catalysis. In 2021, Hojoon joined Merck and Co., Inc. as a Sr. Scientist. Currently, he is part of the Discovery Process Chemistry organization based in Boston, Massachusetts. |

Copyright © 1921-, Organic Syntheses, Inc. All Rights Reserved