Org. Synth. 2013, 90, 174-181

DOI: 10.15227/orgsyn.090.0174

Preparation of N1-Phenylacetamidine 4-Bromobenzoate Using 2,2,2-Trichloroethyl Acetimidate Hydrochloride

Submitted by Lulin Wei and Stéphane Caron

1.

Checked by Margaret Faul, Rob Milburn, and John Colyer.

1. Procedure

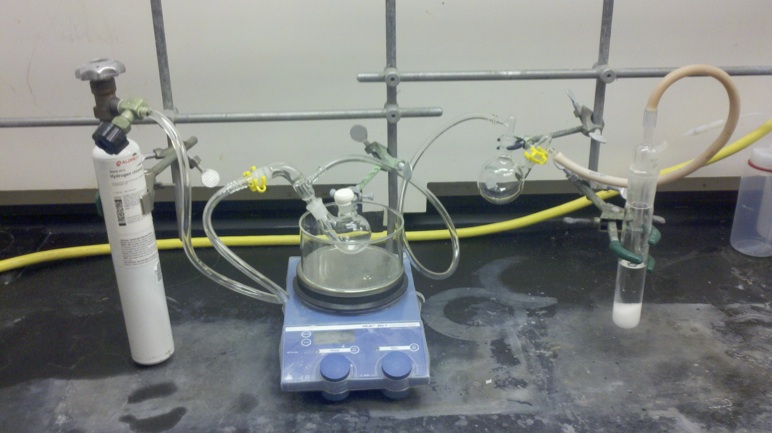

A. 2,2,2-Trichloroethyl acetimidate hydrochloride. To a 50-mL two-necked round-bottomed flask equipped with a thermocouple inserted into the septum and a magnetic stir bar is added acetonitrile (13.0 mL, 248 mmol, 1.19 equiv) (Note 1) and trichloroethanol (20.0 mL, 208 mmol, 1.00 equiv) (Note 2). The flask is capped with a vacuum receiving tube that has the central inlet extended with an Eppendorf pipet tip secured with teflon tape such that the pipet tip extends well into the solution inside the flask (Note 3). The central inlet of the vacuum receiving tube is connected to a hydrogen chloride gas cylinder using Tygon tubing, and the outlet of the vacuum receiving tube is connected via Tygon tubing to an empty 2-necked 150-mL round-bottomed flask (Note 4) that is in turn connected via Tygon tubing to a scrubber (Figure 1) (Note 5). The acetonitrile and trichloroethanol solution is cooled to 0 - 5 °C using an ice bath, and HCl gas is bubbled into the solution for 5 h while maintaining the internal temperature at 0 - 5 °C (Notes 6, 7, and 8). A rate of 10-15 bubbles/min at the scrubber is maintained throughout the 5 h reaction time (Note 9). After complete reaction (Note 10), the flow of HCl gas is stopped; the reaction flask is removed from the ice bath and the stopper removed for approximately 5 min (Note 11). Seed is added to the flask (1 wt%), which is then sealed with a glass stopper and placed in a refrigerator kept at 0 °C for 66 h (Note 12). The product crystallizes as a single solid white mass that is broken up using a spatula and then filtered. The large crystals are further crushed, washed with cold acetonitrile (approx. 0 °C, 3 x 15 mL), and dried in a vacuum oven (125-250 mmHg) at 45 °C to a constant weight (Note 13) to afford 3 as a white solid (42.8-46.0 g, 91-97%) (Note 14).

Figure 1. Apparatus assembly for Step A

B. N1-Phenylacetamidine 4-bromobenzoate. To a 100-mL round-bottomed flask equipped with a magnetic stir bar is added potassium carbonate (12.4 g, 89.9 mmol, 3 equiv) (Note 15), water (30 mL) (Note 16), and 2-methyltetrahydrofuran (20 mL) (Note 17). 2,2,2-Trichloroethyl acetimidate hydrochloride (8.60 g, 37.9 mmol, 1.25 equiv) is added, the biphasic mixture is stirred for 30 min, transferred to a 150 mL separatory funnel and the bottom aqueous layer is discarded. The remaining organic layer is transferred to a 250-mL round-bottomed flask, equipped with a magnetic stir bar, containing aniline (2.76 mL, 30.2 mmol, 1.00 equiv) (Note 18) in 2-methyltetrahydrofuran (100 mL) and the mixture is stirred at room temperature for 3 h. A solution of 4-bromobenzoic acid (6.06 g, 30.1 mmol, 1.00 equiv) (Note 19) in 2-methyltetrahydrofuran (100 mL) is then added and the mixture is stirred at room temperature overnight (Note 20). The resulting solids are filtered, washed with 2-methyltetrahydrofuran (3 x 30 mL), and dried in a vacuum oven (125-250 mmHg) at 45 °C (Note 21) to afford 6 as a white solid (8.88-8.91 g, 87-88%) (Note 22).

2. Notes

1.

Acetonitrile was purchased from Aldrich (271004-100ML, Lot # SHBB9999V) and used as received.

2.

2,2,2-Trichloroethanol was purchased from Aldrich (T54801-100G, lot # BCBG1806V) and used as received.

3.

A 1 mL disposable Eppendorf pipet tip attached to the inlet using teflon tape was used.

4.

The 150-mL 2-necked round-bottomed flask is required to prevent NaOH solution in the scrubber from being sucked back into the reaction during the initial stages of HCl addition.

5.

A Chemglass 29/42 "cold finger" charged with 300 mL of aqueous 5 N NaOH solution was used.

6.

Hydrogen chloride gas was purchased from Aldrich (295426-227G, Lot # MKBJ4524V) and used as received.

7.

An exotherm to ~8 °C is observed within the first 20 min, during which time the rate of HCl addition had to be adjusted to prevent NaOH from being sucked into the trap.

8.

The temperature is maintained by adding ice to the bath.

9.

The rate of bubbling from the scrubber typically remained constant over the first 2 h of the reaction, at which time the flow of HCl was reduced to maintain the 10-15 bubbles/min at the scrubber.

10.

The reaction was typically complete within 5 h as determined by

1H NMR using CH

2 resonance of trichlorethanol (4.86 ppm) and the acetimidate (5.35 ppm) Sample preparation: dilute 100 uL of reaction mixture was with 0.5 mL of DMSO.

11.

This is done to ensure that there is no pressure build up. Temperature should be monitored due to increased off-gassing as the solution warms.

12.

The temperature of the refrigerator was measured at 0 °C. Colder temperature resulted in incomplete crystallization. The yield of the crystallization was increased 5-7% by addition of seed (1% w/w).

13.

Drying was conducted overnight.

14.

2,2,2-Trichloroethyl acetimidate hydrochloride has the following spectroscopic and physical properties: mp 187 °C;

1H NMR

pdf (400 MHz, DMSO-d

6) δ: 2.55 (s, 3 H), 5.35 (s, 2 H), 12.29 (s, 2 H). 1 - 3% of acetamide and trichloroethanol from hydrolysis of

3 are typically observed in the

1H NMR spectrum at δ 2.17 (s, 3 H, CH

3CO), 4.86 (s, 2 H, CCl

3CH

2), 7.31 (br s, 1 H, NH), 7.44 (br s, 1 H, OH), 7.57 (br s, 1 H, NH).

15.

Potassium carbonate (99%) was purchased from Sigma-Aldrich (347825-250G, Lot # MKBJ7723V) and used as received.

16.

Deionized water prepared via a reverse osmosis system was used.

17.

Anhydrous 2-methyltetrahydrofuran was purchased from Sigma-Aldrich (186562-1L, lot # SHBC3613V), and used as received.

18.

Aniline (99.5%) was purchased from Sigma-Aldrich (242284-100ML, Lot # 68396APV) and used as received.

19.

4-Bromobenzoic acid (99%) was purchased from Sigma-Aldrich (108510-100G, Lot # 08231KHV) and used as received.

20.

Solids start to appear after a few minutes

21.

Drying was conducted until all the 2-methyltetrahydrofuran was removed (typically 2-3 days).

22.

N1-Phenylacetamidine 4-bromobenzoate has the following spectroscopic and physical properties: mp 179 °C.

1H NMR

pdf (400 MHz, DMSO-d

6) δ: 2.16 (br s, 3 H), 7.23 (d,

J = 7.6 Hz, 2 H), 7.28 (t,

J = 7.4 Hz, 1 H), 7.44 (t,

J = 8.0 Hz, 2 H), 7.55 (d,

J = 8.6 Hz, 2 H), 7.83 (d,

J = 8.6 Hz, 2 H), 8.83 (br s, 1 H), 11.37 (br s, 2 H);

13C NMR

pdf (100 MHz, DMSO-d

6) δ: 123.8, 124.8, 126.5, 129.4, 130.6, 131.2, 136.5,137.8, 169.9. HRMS: [M + H]

+ calcd for C

8H

10N

2: 135.0917. Found: 135.0920. Anal. Calcd for C

15H

15BrN

2O

2: C, 53.75; H, 4.51; N, 8.36. Found: C, 53.44; H, 4.25; N, 8.28.

Handling and Disposal of Hazardous Chemicals

The procedures in this article are intended for use only by persons with prior training in experimental organic chemistry. All hazardous materials should be handled using the standard procedures for work with chemicals described in references such as "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011 www.nap.edu). All chemical waste should be disposed of in accordance with local regulations. For general guidelines for the management of chemical waste, see Chapter 8 of Prudent Practices.

These procedures must be conducted at one's own risk. Organic Syntheses, Inc., its Editors, and its Board of Directors do not warrant or guarantee the safety of individuals using these procedures and hereby disclaim any liability for any injuries or damages claimed to have resulted from or related in any way to the procedures herein.

3. Discussion

Amidines have been a privileged functional group for the preparation of a wide range of compounds

2-5 and as synthetic intermediates for the elaboration of more complex structures such as heterocycles.

6-8 While the preparations of amidines from amide or nitrile starting materials are well precedented, new synthetic methods to access this functional group have continued to emerge.

9-13 The most common reagent for the preparation of acetamidines is ethyl acetimidate hydrochloride, a stable and relatively inexpensive reagent. Unfortunately, in the case of poor nucleophiles, the reaction can require extensive reaction time and lead to low yields. For instance, the reaction of a 2-amino-1,3,4-thiadazole resulted in a 68% yield after 5 days.

14 We believed that modification of the ethoxy leaving group into a more electron withdrawing moiety would enhance the reactivity of the imidate and expand the scope of amine nucleophiles. Indeed it was demonstrated that the use of trifluoro- and trichloroethyl imidates allows for reactions with a number of different amines to generate amidines.

9 The hydrochloride salts of 2,2,2-trichloro imidates proved to be especially attractive because of their crystallinity and stability. Indeed, we have found that samples of compound

3 stored on the benchtop for a year have not lost potency.

The conversion of imidate 3 to an amidine is conducted by neutralization of the hydrochloride salt and direct use of the 2-MeTHF solution from the extraction. Reaction with an amine generally proceeds rapidly to generate the amidine. We identified the 4-bromobenzoate as a suitable salt for direct crystallization of the amidine. This renders the reaction and isolation of the desired products operationally simple. In the case of aniline (5) this reaction proceeds in >90% yield. Interestingly, the same reaction protocol when conducted with ethyl acetimidate provided a modest ~60% yield.

This procedure has been exemplified using several different amines, as shown in Table 1.

Table 1. Preparation of amidines as p-bromobenzoate salts

Appendix

Chemical Abstracts Nomenclature (Collective Index Number);

(Registry Number)

2,2,2-Trichloroethanol; (115-20-8)

Aniline; (62-53-3)

4-Bromobenzoic acid; (586-76-5)

2-Methyltetrahydrofuran; (96-47-9)

2,2,2-Trichloroethyl acetimidate hydrochloride; (16507-47-4)

N1-Phenylacetamidine 4-bromobenzoate; (1207066-26-9)

|

Stéphane Caron received his B.Sc. and M.Sc. degrees from Université Laval in Canada under the direction of Robert Burnell. He joined the group of Clayton H. Heathcock at the University of California-Berkeley where he received his Ph.D. in 1995 upon completion of the total synthesis of Zaragozic Acid A. He started his industrial career at Pfizer in Groton Connecticut where he is now a Senior Director in Chemical R&D. He is the editor of "Practical Synthetic Organic Chemistry; Reactions, Principles, and Techniques." |

|

Lulin Wei received his B.S. degree in analytic chemistry from Lanzhou University in China and M.S. degree in organic chemistry from Southern Illinois University. After several years studying palladium catalysis in the labs of Professor Richard Larock at Iowa State University, he joined Pfizer in Groton, CT in 1996, where he is currently a senior scientist in Chemical R&D in the Post-POC group. |

|

Robert R. Milburn studied chemistry at the University of Waterloo, Canada and completed an Honors B.Sc in 1996. He then pursued a Ph.D (1997-2002) at Queen's University, Canada under the guidance of Professor Victor Snieckus, exploring organolithiation chemistry and methodology development. After a postdoctoral appointment (2003-2005) at TSRI with Professor K.C. Nicolaou, Robert joined the Chemical Process Research & Development department at Amgen in Thousand Oaks, where he has been involved in the development of synthetic processes of numerous clinical candidates. |

|

John T. Colyer was born in Columbus, Indiana, in 1977. In 2000 he earned his B. S. in chemistry from Indiana University-Purdue University Indianapolis working under the guidance of Professor William H. Moser. He completed his M.S. in 2004 at the University of Arizona under the guidance of Professor Michael P. Doyle, where he studied dirhodium (II) carboxamidate catalysis. In 2004 he joined the Chemical Process Research & Development group at Amgen in Thousand Oaks, CA. |

Copyright © 1921-, Organic Syntheses, Inc. All Rights Reserved