Org. Synth. 2015, 92, 342-355

DOI: 10.15227/orgsyn.092.0342

1,3-Dimethylimidazoyl-2-ylidene borane

Submitted by Sean Gardner, Takuji Kawamoto and Dennis P. Curran

*1

Checked by Fumihiro Wakita and Keisuke Suzuki

1. Procedure

A.

1,3-Dimethyl-1H-imidazol-3-ium iodide (2). A three-necked, 300 mL round-bottomed flask is equipped with a 3.0 cm × 0.6 cm octagonal Teflon-coated magnetic stir bar. The center neck is fitted with a reflux condenser, which is sealed with a rubber septum. One of the side necks is fitted with a rubber septum, and the other is fitted with a three-way stopcock. A nitrogen inlet hose is connected to the three-way stopcock and a nitrogen outlet needle is put into the septum. The flask is dried with a heat gun under vacuum and backfilled with nitrogen. With nitrogen gas flowing,

N-methyl imidazole 1 (4.11 g, 50 mmol) in

dichloromethane (10 mL) is added

via syringe (

Note 1).

Iodomethane (3.74 mL, 60 mmol) is taken up in a syringe, and the needle is inserted into the flask

via the septum. Initially, about 1 mL of

iodomethane is added, upon which the solution warms and boils gently. The remaining

iodomethane is added periodically in portions over about 10 min to maintain a gentle boil. After the addition is complete, the mixture is stirred for 1 h, during which time the solution cools to room temperature (

Note 2). The three-way stopcock is replaced with a rubber septum. Without removing the stir bar, the needle and the condenser are removed and the solvent is concentrated by rotary evaporation (40 °C, 40 mmHg) to give a pale yellow solid of salt

2 (11.3 g) (

Note 3), which is used in the next step without further purification (

Note 4).

Figure 1. 1,3-Dimethyl-1H-imidazol-3-ium iodide

B. 1,3-Dimethylimidazoyl-2-ylidene borane (3). The same three-necked flask is fitted with a reflux condenser on the center neck. A three-way stopcock with a hose, leading to the back of the fume hood, is placed on top of condenser to vent away the hydrogen gas that is generated. One of the side necks is sealed with a rubber septum. The other side neck is fitted with a three-way stopcock connected to a nitrogen inlet hose. After removing the septum, sodium borohydride (2.27 g, 60 mmol) is added by powder funnel. Toluene (50 mL) is added (Notes 5 and 6) to the solution through the funnel, rinsing the solid residues into the flask, and stirring is initiated. The side neck is closed with the septum.

Under a flow of nitrogen gas, the flask is immersed in a 125 °C oil bath. As the mixture nears the reflux point, the imidazolium salt begins to melt. A second ionic liquid phase forms and begins to bubble (

Note 7). As the solution reaches reflux, an ionic liquid phase is visible as a white viscous material on the bottom and the top of the

toluene, with droplets periodically floating up and sinking down through the

toluene, creating exchange between the sunken and floating layers. Over about 8 h, the white liquid phase becomes more viscous and gradually adheres to the inside of the flask. Eventually the top phase and the exchanging droplets disappear. After 20 h at reflux, the mixture is cooled to give a largely clear

toluene phase with a white, glue-like material adhering to the inside of the flask.

Figure 2. Reaction Set-up for Step B

The

toluene phase contains most of the product, and it is carefully decanted from the insoluble viscous material while still hot (

Note 8). Additional

toluene (25 mL) is added to the reaction flask to cover the residue, then the condenser is put back in place and the mixture is heated to reflux to further extract remaining product from the mixture. After 15 min of stirring, the hot

toluene is decanted again. The hot extraction process is repeated once more with fresh

toluene (25 mL). The

toluene extracts are combined, cooled, and concentrated to dryness by rotary evaporation (40 °C, 40 mmHg) to give the crude product (4.38-4.69 g) as a white solid (

Note 9). The solid is recrystallized from water (about 14 mL/g) (

Note 10) and the resulting colorless, needle-shaped crystals of

3 are isolated by vacuum filtration on a Büchner funnel and washed with aliquots of ice-cold water (3 x 5 mL). The crystals are dried under high vacuum (0.3 mmHg) for 12 h at 50 °C to yield 2.58-2.78 g (47-51%) of compound

3 (

Note 11).

|

|

|

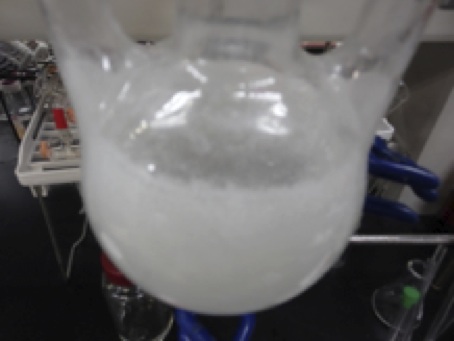

Figure 3. After refluxing 20 h.

|

Figure 4. After decantation.

|

|

|

|

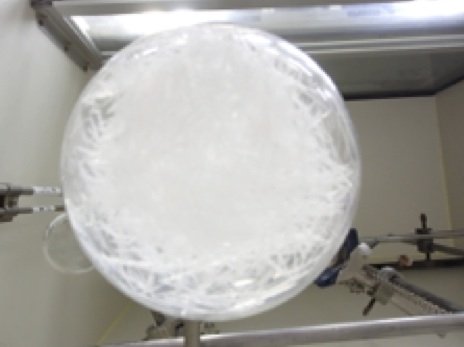

Figure 5. Crude product.

|

Figure 6. Recrystallization.

|

|

2. Notes

1.

Methyl iodide (stabilized with copper chips, 99.5%) and

1-methylimidazole (99%) were purchased from Tokyo Chemical Industry Co., Ltd. and used as received.

Dichloromethane (dehydrated Super) was purchased from Kanto Chemical Co., Inc., and was purified under argon by using Organic Solvent Pure Unit (Wako Pure Chemical Industries, Ltd.) The submitters used as received

methyl iodide (stabilized, 99%) purchased from Acros Organics and

1-methylimidazole (99%) purchased from Sigma-Aldrich.

Dichloromethane (99.9%) was purchased from Fisher Scientific and passed through a column of activated alumina under nitrogen prior to use.

2. A small aliquot is typically removed at this point by capillary pipette and several small drops are added to CDCl

3 (0.5 mL) in an NMR tube. A

1H NMR spectrum is recorded to ensure that

N-methyl imidazole is absent and the salt formation is complete.

3. Due to the extreme hygroscopic nature of the intermediate, the checkers did not determine the melting point of the solid, although the submitters report the mp for crude

2 to be 66-69 °C. Spectral data for crude

2:

1H NMR

pdf(600 MHz, CD

3OD) δ: 3.98 (s, 6 H), 7.628 (s, 2 H), 8.98 (s, 1 H).

13C NMR

pdf(150 MHz, CD

3OD) δ: 37.01, 37.03, 124.87, 124.91, 138.65.

4. The imidazolium iodide (

2) is hygroscopic and becomes sticky or even liquefies during transfer under a humid atmosphere. Thus, the flask for the first reaction is used for the second reaction without material transfer.

5.

Sodium borohydride (95%) was purchased from Tokyo Chemical Industry Co., Ltd. and used as received.

Toluene (dehydrated-Super Plus) was purchased from Kanto Chemical Co., Inc. and used as received. The submitters purchased

sodium borohydride (98%+) from Acros Organics and

toluene (ACS reagent grade) from JT Baker. Both were used as received.

6. A spatula was used to scrape the clumpy solid down beneath the surface of the

toluene, if needed.

7. When the reaction is performed on this scale using a 300 mL flask, the gas bubbles dissipate on the surface of the

toluene during the early stage of the reaction with headspace to spare. With smaller flasks the bubbles tend to foam more, and the foam may rise into the condenser.

8. The clamp is removed from the clamp holder and the clamp is used as a handle to carefully pour the hot

toluene through a glass funnel into another 300 mL round-bottomed flask. The product is not fully soluble in

toluene at ambient temperature and will begin to precipitate if the solution cools prior to the first decantation.

Toluene is a potential recrystallization solvent for this NHC-borane, but water (

Note 10) gives higher recovery and better quality product in this method of synthesis, where the byproducts are likely salts.

9. The crude product may be sufficiently pure for some uses. Good quality

1H and

11B NMR spectral data are provided, though the melting point (128-134 °C) is somewhat depressed. If recrystallization is bypassed, traces of

sodium iodide and other salts can be removed from the crude product by suspension in a small amount of water at room temperature, followed by brief stirring, filtration and vacuum drying.

10. For the recrystallization of the crude material, the checkers used a three-necked, 300 mL round-bottomed flask, in which the crude material and a 3.0 cm × 0.6 cm octagonal Teflon-coated magnetic stir bar were placed, along with about 75% of the calculated volume of water (g of crude material x 14 mL/g x 0.75). The center neck is fitted with a reflux condenser. The side necks are fitted with rubber septa. The flask is open to the atmosphere; the mixture is brought to an oil bath and heated to 100 °C. Small portions of water are repeatedly added through the condenser, while allowing the mixture to come back to a boil between each addition. The additions are repeated until the solid is completely dissolved. The flask with the clear liquid is allowed to cool slowly. The submitters report that the product can also be purified by sublimation; 90-100 °C (heating bath temperature), 2 mmHg.

11. Characterization data of

3: mp 140-141 °C;

1H NMR

pdf(600 MHz, CDCl

3) d: 1.01 (m, 3 H,

J11B-H = 86.2 Hz,

J10B-H = 29.3 Hz), 3.73 (s, 6 H), 6.80 (s, 2 H) ppm.

13C NMR

pdf(150 MHz, CDCl

3) δ: 36.1, 120.0, 172.2 (q,

JB-C = 51.9 Hz).

11B NMR

pdf(128 MHz, CDCl

3) δ: -38.5 (q,

JH-B = 86.3 Hz). IR (NaCl, DR) 3167, 3132, 2999, 2944, 2275, 1575, 1479, 1448, 1235, 1216, 1121, 860, 754, 666, 624 cm

-1. HRMS (ESI)

m/z [C

5H

10BN

2]

+ calcd 109.0933, found 109.0935. Anal calcd for C

5H

11BN

2: C, 54.61; H, 10.08; N 25.47, found C, 54.42; H, 9.73; N, 25.57..

Working with Hazardous Chemicals

The procedures in

Organic Syntheses are intended for use only by persons with proper training in experimental organic chemistry. All hazardous materials should be handled using the standard procedures for work with chemicals described in references such as "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at

http://www.nap.edu/catalog.php?record_id=12654). All chemical waste should be disposed of in accordance with local regulations. For general guidelines for the management of chemical waste, see Chapter 8 of Prudent Practices.

In some articles in Organic Syntheses, chemical-specific hazards are highlighted in red "Caution Notes" within a procedure. It is important to recognize that the absence of a caution note does not imply that no significant hazards are associated with the chemicals involved in that procedure. Prior to performing a reaction, a thorough risk assessment should be carried out that includes a review of the potential hazards associated with each chemical and experimental operation on the scale that is planned for the procedure. Guidelines for carrying out a risk assessment and for analyzing the hazards associated with chemicals can be found in Chapter 4 of Prudent Practices.

The procedures described in Organic Syntheses are provided as published and are conducted at one's own risk. Organic Syntheses, Inc., its Editors, and its Board of Directors do not warrant or guarantee the safety of individuals using these procedures and hereby disclaim any liability for any injuries or damages claimed to have resulted from or related in any way to the procedures herein.

3. Discussion

Interest in the chemistry of N-heterocyclic carbene boranes has increased in recent years following the realization that such compounds are typically stable solids that are convenient to handle in ambient lab conditions and convenient to purify by crystallization or chromagraphy.

21,3-Dimethylimidazoyl-2-ylidene borane 3 was first reported in 2010

3 but has quickly become one of the most commonly used NHC-boranes. Several of its reactions are summarized in Figure 1. It is a precursor to many interesting substituted NHC-boranes, including metal-complexed boranes

3b and boriranes (boracyclopropanes).

4 It undergoes BH insertion reactions with reactive carbenes derived from diazo compounds.

5 It has diverse reduction chemistry as a radical hydrogen atom donor

6 and a neutral hydride source.

7 The compound hydroborates benzyne,

8 but is inert towards standard alkenes and alkynes. However, alkene and alkyne hydroboration can be catalyzed by borenium ions (or their reactive equivalents).

9

Previous routes to

1,3-dimethylimidazoyl-2-ylidene borane 3 are summarized in Figure 2. In essence they all involve complexation of the N-heterocyclic carbene

5 with a borane source. We first made

3 by the deprotonation of

2 with sodium hexamethyldisilylazide to make the NHC

5 in situ, followed by the addition of BH

3•THF.

3a Later we used trimethylamine borane, which is easier to handle then BH

3•THF.

10 However, heating is needed with the amine-borane because of its stability (presumably triethylamine must be released from the amine-borane to allow complexation with the NHC).

Braunschweig made

3 from the NHC-carboxylate

4 and BH

3•SMe

2.

3b These methods all require exclusion of air and moisture either because of the base, the borane, or both. The products from these preparations were purified by flash chromatography or precipitation with hexane.

The procedure described above is fashioned after reactions of some amine salts and with alkali metal borohydrides to make amine-boranes.

11 Compared to the borane sources, the borohydride is less expensive and easier to handle. The iodide counterion is used because the imidazolium iodide is easy to make and because it melts below the boiling point of

toluene. The iodide is made by a variant of Zoller's procedure

12 where slow addition of

methyl iodide starting at ambient temperature replaces rapid addition with cooling. The cooling method can be problematic because the methylation is not fast at 0 °C. If all the

methyl iodide is added but the reaction does not progress in the cold, then a very exothermic reaction can occur suddenly as the solution is warmed to room temperature.

The solvent toluene is an important component in Step B even though neither of the precursors is very soluble, even at reflux. Extensive frothing and foaming occurred when the iodide salt was melted without solvent in the presence of sodium borohydride. When the reaction was conducted by heating in dioxane, the NHC-borane was typically formed in much lower yields (10-20% isolated) alongside large amounts of water-soluble byproducts that appear to be amines or polyamines (many resonances between 2-3 ppm in the 1H NMR spectrum). Lesser amounts of these byproducts form in this procedure, and they remain trapped in the glue-like phase that adheres to the flask.

Compared to the neat (solvent-free) reaction, toluene helps to prevent foaming. During the early stage of the reaction in toluene, an ionic liquid phase forms as the imidazolium iodide melts. This phase is simultaneously present above, below, and suspended in the toluene. The droplets suspended within the toluene are variously floating up or sinking down. We call this the "lava lamp" stage of the reaction, and it lasts several hours.

The initial ionic liquid phase presumably contains the melted imidazolium iodide and sodium borohydride. In principle, this phase is more dense than toluene. However, we speculate that as the reaction occurs and dihydrogen and the NHC-borane are formed, the local density of the ionic liquid phase decreases in places. Droplets break off and float to the surface. On the way to or at the surface, the hydrogen gas is released to the atmosphere and the NHC-borane is released to the toluene. The density of the ionic liquid droplet then increases, so it sinks back down.

Regardless of whether this procedure or another is followed to make

3, we recommend the use of water as a recrystallization solvent because it gives sparkling white crystals in high purity and with good recovery. That

3 can actually be recrystallized from hot water is a clear testament to its water stability. Indeed, the structure of

3 seems to be a kind of sweet-spot for water recrystallization. Addition of more or larger alkyl or aryl substituents quickly decreases the solubility of NHC-boranes in hot water. Going in the other direction, a triazolium analog of

3 has increased water solubility.

13NHC complexes of borane are not pyrophoric, and we routinely weigh and transfer

3 and other NHC-boranes in air. The autoxidation of

3 has not been studied, but it could well occur under suitable conditions in solution.

14 However, solid samples of

3 have been stored at ambient temperatures without exclusion of air for long periods (> 1 year) without evidence of significant decomposition.

This and other carbene boranes are potential bases and reducing agents, and should be stored and handled as such. Acids with pKa's less than about 1-2 react instantly with typical NHC-boranes to form dihydrogen.

15 Likewise, as mild reductants

7c NHC-boranes are expected to react vigorously with strong oxidants. To verify this, we added one drop of 70% nitric acid to a few milligrams of

3. In various trials it either ignited instantly with a flash of flame and an audible pop, or sizzled and smoked vigorously for a few seconds. Accordingly,

3 and presumably other NHC-boranes are potentially hypergolic (spontaneously ignite on contact) with strong oxidants.

16Like their borohydride and amine-borane cousins, NHC-boranes should be stored separately from acids or oxidants. And they should not be added to any waste with acids or oxidants. Even if no initial reaction is noticed, it is likely that pressure will build in sealed containers over time due to formation of gases (minimally dihydrogen and perhaps other gases depending on the acid or oxidant).

A short study of the scope and limitations of this procedure has recently appeared.

17 Briefly, 1,3-dialkylimidazolium salts form NHC-boranes provided that the melting point of the salt is below the boiling point of

toluene. The ionic liquid phase does not form if the salt does not melt.

Appendix

Chemical Abstracts Nomenclature (Registry Number)

1-Methylimidazole: H-Imidazole, 1-methyl-; (1) (616-47-7)

Methyl iodide: Methane, iodo-; (74-88-4)

1,3-Dimethyl-1H-imidazol-3-ium iodide: 1H-Imidazolium, 1,3-dimethyl-, iodide: (2) (4333-63-4)

Sodium borohydride: Borate(1-), tetrahydro-, sodium (1:1); (16940-66-2)

Toluene: Benzene, methyl-; (108-88-3)

1,3-Dimethylimidazol-2-ylidene borane: boron, (1,3-dihyro-1,3-dimethyl-2H-imidazol-2-ylidene)trihydro-; (3) (1211417-77-4)

|

Sean R. Gardner received his B.S. in chemistry from Drexel University in 2008, where he worked under the supervision of Dr. Elizabeth T. Papish. He is currently pursuing his graduate studies under the supervision of Professor Dennis P. Curran. His research focuses on the synthesis of N-heterocyclic carbene borane complexes and development of novel reaction methodologies. |

|

Takuji Kawamoto obtained his B.S. degree (2009), M.S. degree (2011), and Ph.D. degree (2014) from Osaka Prefecture University (Japan) under supervision of Professor Ilhyong Ryu. Then he studied as a postdoctoral fellow with Professor Dennis P. Curran at University of Pittsburgh (USA). His postdoctoral research mainly focused on carbon-boron bond forming reactions via radical intermediates. He is currently working at Yamaguchi University (Japan) as an assistant professor. |

|

Dennis P. Curran was born in Easton, Pennsylvania in 1953. He obtained a BS in 1975 from Boston College, then a Ph.D. in 1979 from the University of Rochester (with A. S. Kende). After postdoctoral work at the University of Wisconsin (with B. M. Trost), he joined the University of Pittsburgh in 1981. He is currently a Distinguished Service Professor and the Bayer Professor of Chemistry. He is the editor of Volume 83 of Organic Syntheses. |

|

Fumihiro Wakita was born in 1990 in Amami Ōshima, Japan. He received his M.Sc. degree from Waseda University in 2015. In the same year, he joined the research group of Prof. Keisuke Suzuki at Tokyo Institute of Technology. His research focuses on the synthesis of natural products. |

Copyright © 1921-, Organic Syntheses, Inc. All Rights Reserved