1. Procedure

A.

4-Methyl-2-(p-tolyl)pentanoic acid (1). An oven-dried 1-L, one-necked round-bottomed flask fitted with a 4 x 2 cm egg-shaped stir bar is cooled under a stream of nitrogen.

p-Tolylacetic acid (

Note 1) (17.06 g, 114 mmol, 1 equiv) is added and the flask is sealed with a rubber septum.

Tetrahydrofuran (

THF) (

Note 2) (~700 mL) is added by cannula and the flask is placed under a nitrogen atmosphere delivered through an 18-gauge needle. The solution is cooled to 0 °C and stirred vigorously (

Note 3).

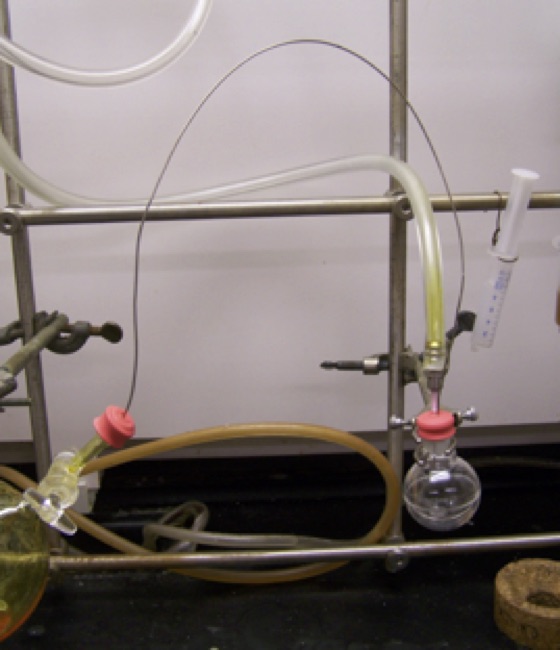

n-Butyllithium (2.5 M in

hexane, 100 mL, 250 mmol, 2.2 equiv) is added dropwise by cannula (

Note 4) (Figure 1). The reaction is maintained at 0 °C for 90 min, at which point

isobutyl bromide (16.0 mL, 148 mmol, 1.3 equiv) (

Note 5) is added via a 30 mL syringe over a period of 15 min, causing the reaction to turn yellow. The reaction is allowed to warm to room temperature slowly (

Note 6) and stirred overnight (ca. 18 h). The completion of the reaction is checked by TLC (

Note 7). The reaction is quenched by the addition of

water (150 mL), which causes the reaction to turn from a white-yellow suspension into a clear and biphasic system. The volatile components are removed by rotary evaporation (35 ºC, 4 mmHg). The solution is then acidified to pH 1 (

Note 8) by addition of concentrated

HCl (~15 mL) over a period of 5 min. The aqueous layer is extracted with

diethyl ether (4 x 150 mL). The combined organic extracts are dried over

MgSO4, filtered, and concentrated by rotary evaporation (30 ºC, 4 mmHg). The residue is placed under high vacuum with stirring (0.2 mmHg) over 12 h to yield the product as a white solid (23.0 g, >99%) (Notes

9 and

10).

Figure 1. Addition of n-BuLi to p-Tolylacetic acid

C.

4-Methyl-2-(p-tolyl)pent-1-en-1-one (3). All glassware is oven dried. A 300-mL schlenk tube with a 2.5 cm wide valve and 24/40 joint is fitted with a 3.2 x 1.6 cm egg-shaped stir bar and a rubber septum (

Note 17). The flask is purged (0.4 mmHg) and backfilled with dry nitrogen through an 18 G needle three times as it is allowed to cool to room temperature. Compound

2 is then added via 20 mL syringe (10.8 g, 48 mmol, 1 equiv), followed by

diethyl ether (150 mL) via 50 mL syringe. The solution is stirred (

Note 18) and

dimethylethylamine (20.7 mL, 192 mmol, 4 equiv) (

Note 19) is added via multiple uses of a 20 mL syringe, and the reaction begins to turn yellow and a white precipitate begins to form in the yellow solution (Figure 3, left). The valve on the schlenk flask is closed and the reaction is stirred for 72 h. The reaction is then filtered as follows (Figure 3, right): a 1-necked (24/40) 500 mL round-bottomed flask with a sidearm with a ground-glass stopcock (stopcock A) is placed under a stream of argon through tube A, and fitted with a 100-mL schlenk filter with a sidearm with a ground-glass stopcock (stopcock B) and 14/20 female ground glass joint. A tube is connected to the schlenk line and to the filter's sidearm at stopcock B.

Figure 3. Reaction Assembly for Step B and Filtration Assembly

The septum is removed from the reaction vessel and the vessel placed on top of the filtration apparatus. Stopcock A is closed, and the filter apparatus is purged by applying a vacuum (0.5 mmHg) via stopcock B and backfilling with argon three times. With stopcock A closed, the tube attached to the lower stopcock (tube A) is placed under vacuum. The reaction vessel's valve is then opened slowly. When ~3 cm of reaction mixture has collected above the frit, vacuum is gently applied to the flask by quickly opening and closing stopcock A. If the level of reaction mixture approaches stopcock B, the schlenk flask's valve is closed temporarily to prevent the reaction mixture from entering tube B. When all of the liquids have entered the collection flask, stopcock B is closed, and the solvent and excess amine are removed under high vacuum. The collection flask is placed in a warm water bath (~30 °C) to expedite the concentration, which takes ~30 minutes. Stopcock A is closed, and the apparatus backfilled with argon through stopcock B. The tube attached to stopcock A is backfilled with argon and removed from the apparatus, a rubber septum is placed over the end of the sidearm, and tube A is fitted with a luer-lock connector and a 1.5" 18 gauge needle. A 50-mL round-bottomed flask with a 14/20 ground glass joint is fitted with a rubber septum, which is pierced with the needle on tube A. A cannula is placed between the 50-mL flask and the septum on sidearm A (Figure 4). The flask, cannula, and end of the sidearm are purged (0.6 mmHg) and backfilled with argon three times. Stopcock A is then opened and the crude ketene is transferred to the round-bottomed flask.

Figure 4. Cannula placed between Round-bottomed Flask and the Schlenk Flask

The flask is backfilled with argon and the cannula removed. The septum is removed from the 50-mL flask and the flask is immediately attached to a vacuum distillation apparatus equipped with a multiflask collector (Figure 5) with tared receiving flasks. The distillation apparatus is then purged (0.5 mmHg) and backfilled with argon three times. The ketene is then distilled in one fraction (0.15 mmHg, 120 °C) (

Note 20). Upon completion of the distillation, the apparatus is refilled with argon. The receiving flask is removed, and is quickly equipped with a septum. Compound

3 is obtained as a yellow liquid (6.30 g, 70%) (Notes

20,

21, and

22).

Figure 5. Distillation Apparatus used in Step C

2. Notes

1. Unless otherwise noted all chemicals were purchased from Sigma-Aldrich (reagent grade) and used without further purification.

p-Tolylacetic acid (99%) was purchased from Acros.

2.

THF (Fisher, HPLC grade, 99.9%) and ether (Fisher, ACS, 99,9%) used as reaction solvents were sparged with dry nitrogen, and subsequently passed over columns of activated alumina and Q5 catalyst.

3. The reaction is stirred at 900-1000 rpm. The monoanion of

p-tolylacetic acid is highly insoluble and a thick white slurry forms over the first half of the addition and dissipates over the second half.

4. An entire 100 mL bottle of

n-butyl lithium is added over a period of approximately 20 minutes. The submitters generally used fresh

n-butyl lithium, but unopened samples that had been stored at -10 ºC for two months were just as effective. The checkers used fresh

n-butyl lithium.

5. Reagent grade

isobutyl bromide (99%) was purchased from Sigma-Aldrich and used as received.

6. It is important to leave the flask in the ice bath. If the ice bath is removed, butane is evolved vigorously.

7. A 0.5 mL aliquot of the reaction is added to a mixture of 1 mL

water, 1 mL

EtOAc, and 5 drops concentrated

hydrochloric acid. A TLC is taken of the organic layer,

p-tolylacetic acid, and a co-spot of starting material and the reaction mixture. Aluminum backed Silica gel 60 F

254 plates were purchased from EMD Chemicals Inc. The TLC plate was eluted with pure

ethyl acetate, and the plate was visualized under 254 nm UV light. The R

f of the starting material was 0.79, and the R

f of the product was 0.91.

8. pH was determined by EMD Millipore colorpHast® pH Test Strips.

9. The reaction was performed at half-scale and provided 11.8 g (>99%) of a white solid.

10. Compound

1 displays the following physiochemical properties: R

f = 0.43 (30% ethyl acetate / 70% hexanes), mp 61-63 ºC,

1H NMR

pdf(500 MHz, CDCl

3) δ: 0.91 (d,

J = 6 Hz, 6H), 1.48 (m, 1H), 1.66 (m, 1H), 1.92 (m, 1H), 2.33 (s, 3H), 3.63 (t,

J = 8 Hz, 1H), 7.14 (d,

J = 8 Hz, 2H), 7.22 (d,

J = 8 Hz, 2H);

13C NMR

pdf(125 MHz, CDCl

3) δ: 21.1, 22.2, 22.7, 25.8, 42.0, 49.1, 128.0, 129.4, 135.7, 137.2, 180.7; IR (KBr) 2957, 273, 2644, 1702, 1513, 1466, 1437, 1413, 1386, 1370, 1324, 1300, 1286, 1252, 1213, 1189, 1120, 1044, 943, 835, 790, 727, 693, 669, 636, 503 cm

-1; HRMS (ESI) [M - H]

+ calcd for C

13H

17O

2 205.1234, found; 205.1238; Anal. Calcd. for C

13H

18O2: C, 75.69; H, 8.80. Found: C, 75.43; H, 8.86.

11.

Thionyl chloride (ReagentPlus, 99.5%, low iron) was purchased from Sigma Aldrich and used as received.

12. Anhydrous

Potassium carbonate (Reagent grade, 100.6% assay) was purchased from JT Baker.

13. It is imperative to apply vacuum slowly to prevent bumping both on the rotovap and the vacuum distillation assembly.

14. The submitters reported the distillation was performed through the use of a Kugelrohr apparatus.

15. When the reaction was performed on a slightly larger scale, the identical product was obtained (14.4 g, 86%).

16. Compound

2 should be used immediately as it is water reactive. It displays the following spectroscopic properties:

1H NMR

pdf(500 MHz, CDCl

3) δ: 0.93 (dd,

J = 3, 7 Hz, 6H), 1.51 (dt,

J = 14.2, 6.6 Hz, 1H), 1.75 (m, 1H), 2.04 (m, 1H), 2.36 (s, 3 H), 4.03 (t,

J = 8 Hz, 1 H), 7.19 (s, 4H);

13C NMR

pdf(125 MHz, CDCl

3) δ: 21.1, 22.0, 22.7, 25.6, 42.0, 61.2, 128.3, 129.8, 133.0, 138.1, 175.2; IR (film) 2951, 2871, 1789, 1514(m), 1468, 1387, 1369, 1255, 1170, 1127, 1038, 982, 875, 840, 820, 751, 729, 703, 561, 541, 446 cm

-1; HRMS (EI) [M+] calcd for C

13H

17OCl: 224.0968. Found: 224.0972. Anal. Calcd. for C

13H

17ClO: C, 69.48; H, 7.62. Found: C, 69.49; H, 7.59.

17. Sigma-Aldrich SKU Z124656 for 24/40 joints, Z124591 for 14/20 joints.

18. The reaction is stirred between 700-900 rpm to maintain the amine hydrochloride salt in suspension.

19.

Dimethylethylamine (Sigma-Aldrich, 97%) was distilled from CaH

2 (90-95%, Alfa-Aesar) and stored in bottles over KOH in a dessicator with drierite. This compound is stable for at least 7 months stored in this fashion.

20. Compound

3 must be stored under an inert atmosphere. Ketenes are sensitive to water, heat, and light. The submitters report that aryl alkyl ketene are stable indefinitely in a nitrogen-filled glovebox at -40 °C. When determining the mass of the compound, the impact of the inert atmosphere must be considered.

21. A reaction performed on half scale provided the same product (3.20 g, 71%).

22. Compound

3 displays the following physiochemical properties:

1 H NMR

pdf(500 MHz, C

6D

6) δ: 0.79 (d,

J = 7 Hz, 6 H), 1.61 (m, 1 H), 1.96 (d,

J = 7 Hz, 2 H), 2.10 (s, 3 H), 6.89 (d,

J = 8 Hz, 2 H), 6.95 (d,

J = 8 Hz, 2 H);

13C NMR

pdf(125 MHz, C

6D

6) δ: 21.0, 22.4, 27.4, 33.4, 37.8, 124.8, 129.7, 130.1, 134.0, 206.3; IR (film): 2957, 2925, 2869, 2096, 1819, 1747, 1608, 1513, 1466, 1385, 1367, 1243, 1124, 1020, 935, 809 cm

-1. HRMS (EI) [M+] calcd for C

13H

16O: 188.1201; Found: 188.1200. Anal. Calcd. for C

13H

16O: C, 82.94; H, 8.57. Found: C, 82.58; H, 8.40.

3. Discussion

Ketenes are useful synthetic building blocks due to their propensity to undergo [2 + 2] cycloaddition reactions with several different partners including alkenes

2, aldehydes or ketones

3, and imines

4 to form a cyclobutanones, β-lactones, and β-lactams. Nucleophiles can also add to the O=

C=C carbon.

5 These reactions have been reviewed extensively.

6 Recently, chiral nucleophilic catalysts or chiral auxiliaries have been employed to impart enantioselectivity on these cycloadditions

7 and addition

8 reactions. Furthermore, reports of transition metal catalyzed carbon-carbon bond forming reactions of ketenes are beginning to emerge, including a Ni catalyzed [2 + 2 + 2] cycloaddition reaction of diynes and ketenes, which forms cyclohexadienones

9, and a Rh catalyzed three component reaction of silyl acetylene and two ketenes, which forms 1,3-enynes bearing carboxylic esters.

10 These reactions are of particular interest as they resist decarbonylation of transition-metal ketene complexes, which forms unreactive metal carbonyl complexes.

11

Scheme 1. Reactions of Ketenes

Several other methodologies exist to generate ketenes: cracking of ketene dimers,

12 pyrolysis of anhydrides,

13 Wolff rearrangement of α-diazo ketones,

14 and reduction of α-halo acid halides

15. These methods require high temperatures, formation and handling of diazo compounds, low substrate scope, and/or extra steps. Trapping of ketenes

in situ16 is much more common than isolating reactive ketenes due to their tendency to dimerize, and most of these reactions produce by-products that make isolation difficult. Dehydrohalogenation

17 is therefore the most popular method of synthesizing and isolating ketenes. Some ketenes prepared in this communication have been previously reported,

7d,7e,8a,10,18 albeit on smaller scale. These reported preparations lack the detail essential for an

Organic Syntheses article, and are lower yielding, presumably due to the smaller scale.

Copyright © 1921-, Organic Syntheses, Inc. All Rights Reserved