Org. Synth. 2021, 98, 491-508

DOI: 10.15227/orgsyn.098.0491

Stereoselective [2+2] Cycloadditions: Synthesis of a Tri-O-Bn-D-Glucal-derived β-Lactam

Submitted by Maria Varghese,

& Hannah E. Caputo,

& Ruiqing Xiao,

& Anant Balijepalli,

# Aladin Hamoud,

& and Mark W. Grinstaff

1,&,#,*Checked by Kyohei Oga, Masanori Nagatomo, and Masayuki Inoue

1. Procedure (Note 1)

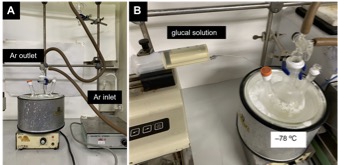

A. (1S,3R,4S,5R,6R)-4,5-Bis(phenylmethoxy)-3-[(phenylmethoxy)methyl]-2-oxa-8-azabicyclo[4.2.0]octan-7-one (1). An oven-dried 500 mL three-necked round-bottomed flask is equipped with an oven-dried 3 cm Teflon-coated magnetic stir bar and oven-dried sodium carbonate (4.00 g, 37.7 mmol, 1.6 equiv) (Note 2). The right neck is fitted with an oven-dried 15/25 glass stopper (Note 3). The left neck is fitted with a 15/25 rubber septum, and the central neck is equipped with a 29/32 three-way cock connected to an argon inlet and a vacuum line. The flask is evacuated and backfilled with argon gas three times. Argon atmosphere is maintained throughout the reaction under argon flow (Figure 1A). Anhydrous toluene (40 mL) (Note 4) and chlorosulfonyl isocyanate (CSI) (2.72 mL, 4.42 g, 31.2 mmol, 1.3 equiv) (Notes 5 and 6) are added at room temperature (26 °C) to the 500 mL three-necked round-bottom flask using 60 mL and 6 mL disposable syringes, respectively. The reaction flask is cooled to -78 °C (bath temperature) in a dry ice and methanol bath within a 1 L Dewar cooling bath (Note 7).

Figure 1. (A) Reaction set-up; (B) Addition of glucal solution at -78 °C (photos provided by checkers)

A solution of tri-O-benzyl-D-glucal (2, 10.0 g, 24.0 mmol) (Note 8) in toluene (40 mL) is added via a 60 mL disposable syringe and a syringe pump to the stirring CSI solution in the three-necked round-bottomed flask at -78 °C. The solution was added dropwise at a rate of 1.5 mL/min (Note 9) (Figure 1B) resulting in a yellow solution. After the addition is completed, the reaction mixture is warmed to -62 °C using a constant temperature bath with methanol (Note 10) (Figures 2A and 2B) and stirred for 3 h at this temperature.

The reaction mixture is cooled to -78 °C in dry ice and methanol bath (Figure 2C). Then the reaction mixture is diluted with anhydrous toluene (120 mL: 60 mL x 2) using a 60 mL disposable syringe and syringe pump over 30 min at a rate of 4 mL/min (Figure 2D). Red-Al® (>60 wt % solution in toluene, 10.9 mL, 7.08 g, 35.0 mmol, 1.46 equiv) (Notes 11 and 12) is added to the three-necked, round-bottomed flask using a 12 mL disposable syringe and syringe pump over 15 min at a rate of 0.6 mL/min (Figure 2E).

Figure 2. (A and B) Raising temperature of reaction solution to -62 °C; (C) Cooling temperature of reaction solution to -78 °C; (D and E) Addition of toluene and Red-Al® (photos provided by checkers)

After being stirred at -78 °C for 15 min, the reaction mixture is warmed to -62 °C and stirred for 10 min. The solution is warmed to -10 °C and stirred for 10 min in an ice and acetone bath (Note 13) (Figure 3A). The reaction mixture is effervescing and is slightly yellow at this point. The reaction is quenched by dropwise addition of deionized water (1.0 mL) over one min using a disposable syringe. The resultant mixture is stirred for an additional 15 min while warming up the mixture to 0 °C (Figure 3B) in ice water and then stirred another 15 min, at which time the solution is at 26 °C (Figure 3C) (Note 14).

Figure 3. Raising temperature of reaction solution to (A) -10 °C; (B) 0 °C; (C) 26 °C (photos provided by checkers)

The solution is then filtered via vacuum filtration with a Büchner funnel and filter paper (Note 15) to remove solids. The solid is washed with ethyl acetate (300 mL), and the filtrate is transferred to a 2 L round-bottomed flask. The resultant solid on the filter paper is transferred to a 500 mL separation funnel using deionized water (200 mL), and ethyl acetate (100 mL) is added to the separation funnel. The aqueous layer is extracted with ethyl acetate (100 mL x 2), and the organic layers are combined into the above 2 L round-bottomed flask. The solution is concentrated by rotary evaporation (37 °C, from 400 mmHg to 20 mmHg). The residue is transferred to a 500 mL separation funnel using ethyl acetate (200 mL). The organic layers are washed with 1 M HCl solution (200 mL), saturated sodium bicarbonate (200 mL), and brine (200 mL). The organic layers are dried over sodium sulfate (10 g) to remove residual water, and the drying agent is filtered via vacuum filtration with a Büchner funnel and filter paper (Note 15) into a 1 L round-bottomed flask. The filtrate is concentrated by rotary evaporation (37 °C, from 400 mmHg to 20 mmHg) to obtain a crude yellow oil (5.10 g).

The crude yellow oil is purified by flash column chromatography on silica gel (150 g) (Note 16) using ethyl acetate and n-hexane as eluents (Note 17). The desired product is obtained in fractions 16-22, combined, and concentrated by rotary evaporation (37 °C, from 400 mmHg to 10 mmHg) to yield a colorless oil. The oil is then placed under high vacuum(27°C, 5 mmHg) for 20 h to afford 3.95 g (36%, 97.9% purity) of (1S,3R,4S,5R,6R)-4,5-Bis(phenylmethoxy)-3-[(phenylmethoxy) methyl]-2-oxa-8-azabicyclo[4.2.0]-octan-7-one (1) as a white solid (Figure 4) (Notes 18, 19 and 20).

Figure 4. Purified title compound 1 (photos provided by checkers)

2. Notes

1. Prior to performing each reaction, a thorough hazard analysis and risk assessment should be carried out with regard to each chemical substance and experimental operation on the scale planned and in the context of the laboratory where the procedures will be carried out. Guidelines for carrying out risk assessments and for analyzing the hazards associated with chemicals can be found in references such as Chapter 4 of "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at

https://www.nap.edu/catalog/12654/prudent-practices-in-the-laboratory-handling-and-management-of-chemical. See also "Identifying and Evaluating Hazards in Research Laboratories" (American Chemical Society, 2015) which is available via the associated website "Hazard Assessment in Research Laboratories" at

https://www.acs.org/content/acs/en/about/governance/committees/chemicalsafety/hazard-assessment.html. In the case of this procedure, the risk assessment should include (but not necessarily be limited to) an evaluation of the potential hazards associated with

sodium carbonate,

toluene,

chlorosulfonyl isocyanate, dry ice,

methanol,

tri-O-benzyl-d-glucal,

Red-Al® [sodium bis(2-methoxyethoxy)aluminum hydride solution (>60 wt% solution in

toluene)],

acetone,

isopropanol,

ethyl acetate,

cyclohexane,

hexanes,

sodium bicarbonate, 1 M

HCl solution, silica gel,

CDCl3, and

duroquinone, as well as the proper procedures for preparation of the

CSI reagent and quenching of the

CSI and

Red-Al®.

2.

Sodium carbonate was purchased from Millipore Sigma (submitters) and Nacalai Tesque, Inc. (checkers).

3. A 500 mL three-necked, round-bottomed flask containing

sodium carbonate (~9.0 g), a Teflon-coated stir bar, and two glass stoppers are dried overnight (12 h) in an oven at 120 °C. Upon removal from the oven, a stir bar is added to the round-bottomed flask, and the flask is fitted with two glass stoppers. Glassware is cooled to room temperature under a vacuum before proceeding.

4. Reagents and solvents used in this procedure, except

chlorosulfonyl isocyanate (

CSI), are commercially available and were used without further purification. This includes

ethyl acetate,

hexanes, and

toluene purchased from Pharmco (submitters).

Ethyl acetate (>99%) and

n-hexane (>95%) were purchased from Kanto Chemical Co., Inc. and were used as received (checkers). Anhydrous

toluene was purchased from FUJIFILM Wako Pure Chemical Corporation and purified by Glass Contour solvent dispensing system (Nikko Hansen & Co., Ltd.) (checkers).

5. The liquid reagent

chlorosulfonyl isocyanate (

CSI) is a highly toxic and corrosive chemical that reacts violently with water and is a lachrymator. Extreme care should be taken when using this reagent. To remove the contaminants (

sulfur trioxide and

hydrogen chloride) in commercially available

CSI, the

CSI is mixed with oven-dried

sodium carbonate (120 °C, 12 h) and stored for at least one week in the refrigerator (0-4 °C) prior to use (checkers) (Figure 5).

CSI was colorless before the reaction. The

CSI is warmed up to room temperature before starting the reaction. The leftover

CSI is diluted with

cyclohexane and quenched by dropwise addition of

isopropanol (submitters).

Figure 5. Color of CSI (A) Before purification; (B) After purification (photos provided by checkers)

6.

Chlorosulfonyl isocyanate (98 %) was purchased from Sigma Aldrich (submitters and checkers).

7. In a 1 L Dewar cooling bath, approximately 500 g of dry ice and 250 mL of

methanol were used to set the bath temperature at -78 °C. All temperatures reported in the procedure are bath temperatures.

8.

Tri-O-benzyl-D-glucal (

2) (98%) was purchased from Carbosynth (submitters and checkers).

9. Faster addition will decrease the yield and stereoselectivity because of the increase in the overall temperature of the reaction mixture leading to degradation of intermediate or a mixture of stereoisomers.

10. A constant temperature bath (UCR-150N-S, Techno Sigma Co., Ltd.) was used (checkers).

11.

Red-Al®,

sodium bis(2-methoxyethoxy)aluminum hydride solution (>60 wt% in

toluene), was purchased from Sigma Aldrich (submitters and checkers).

12.

Red-Al® is a highly toxic and flammable liquid that reacts violently with water. Extreme care should be taken when using this reagent. This is a highly dense reagent. Therefore a 21 G needle should be used for transferring the reagent. The leftover reagent in the syringe should be diluted with

hexanes and quenched by dropwise addition of

isopropanol (submitters).

13. In a 1 L Dewar cooling bath, approximately 200 g of ice and 200 mL of

acetone were used to set the bath temperature at -10 °C.

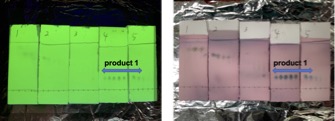

14. TLC analyses of the reaction mixture are shown below (Figure 6) (checkers). The spot of the product can be visualized by fluorescence on silica gel 60 F

254 plates (TLC Silica gel 60 F

254, purchased from Merck KGaA) with UV light (254 nm) and by anisaldehyde stain. R

f = 0.33 (1:1

n-hexane :

ethyl acetate).

Figure 6. TLC analysis of reaction mixture (A) Before the addition of Red-Al®; (B) 40 minutes after the addition of RedAl®; (C) Crude mixture (photos provided by checkers)

15. The filter paper (No. 1, diameter: 9 cm) was purchased from Tokyo Roshi Kaisha, Ltd.

16. Silica gel (Silica gel 60N, spherical and neutral, 0.040-0.050 mm) was purchased from Kanto Chemical Co., Inc. and used as received (checkers).

17. The column chromatography is run as follows: A flash column (6 cm column diameter) is charged with sea sand to a height of 1 cm and then with silica gel (150 g) using a wet-pack method to give a column height of 13 cm. Sea sand with 1 cm minimum height is added to the to the top of the column. The crude oil is loaded onto the column using 15 mL of

n-hexane/

ethyl acetate (2/1, v/v). At this point, fraction collection (200 mL x 25) is begun, and elution is continued with 2 L of

n-hexane/

ethyl acetate (2/1, v/v), then 4 L of

n-hexane/

ethyl acetate (1.5/1, v/v), then 4 L of

n-hexane/

ethyl acetate (1/1, v/v) (checkers).

18. The product is stable for up to 6 months if stored at -20 °C (submitters).

19.

(1S,3R,4S,5R,6R)-4,5-Bis(phenylmethoxy)-3-[(phenylmethoxy)methyl]-2-oxa-8-azabicyclo[4.2.0]octan-7-one: mp (uncorrected) = 72-75 °C; R

f = 0.33 (1:1

n-hexane :

ethyl acetate, visualized by UV and anisaldehyde stain) (Figure 7);

1H NMR

pdf (400 MHz,

CDCl3) δ: 3.34 (m, 1H), 3.57 (dd,

J = 9.1, 6.8 Hz, 1H), 3.57-3.65 (m, 2H), 3.95 (m, 1H), 4.04 (dd,

J = 6.8, 2.8 Hz, 1H), 4.42-4.53 (m, 4H), 4.62 (d,

J = 11.9 Hz, 1H), 4.69 (d,

J = 11.4 Hz, 1H), 5.44 (d,

J = 4.1 Hz, 1H), 6.27 (brs, 1H), 7.10-7.13 (m, 2H), 7.19-7.34 (m, 13H).

13C NMR

pdf (100 MHz,

CDCl3) δ: 54.8, 69.3, 69.6, 71.1, 73.4, 73.5, 75.6, 76.2, 99.8, 127.7 (2C), 127.8 (5C), 128.0 (2C), 128.3 (2C), 128.35 (2C), 128.43 (2C), 137.4, 137.7, 137.9, 167.0. IR (KBr film): 3289, 3030, 2868, 1768, 1495, 1453, 1362, 1263, 1208, 1109, 738 cm

-1. HRMS (ESI).

m/

z [M + Na]

+ calc'd for [C

28H

29NO

5Na]

+: 482.1938; found 482.1929. Purity of the lactam (28.04 mg) was assessed 97.9% by

1H qNMR

pdf using

duroquinone (10.82 mg) as the internal standard, which was purchased from Sigma Aldrich with 99.7% purity. Based on this purity, the corrected yield is 3.86 g (35%); The purity of the lactam was also assessed by elemental analysis (Calculated: C: 73.18, H: 6.36, N: 3.05; Observed: C: 72.95, H: 6.57, N: 3.10).

Figure 7. TLC analysis of column fractions (A) Spots on silica gel plate visualized under UV light (254 nm). (B) Anisaldehyde stain (photos provided by checkers)

20. The reaction was also performed on half scale and yielded 1.89 g (34%, 98.8% purity) of the lactam product.

Working with Hazardous Chemicals

The procedures in

Organic Syntheses are intended for use only by persons with proper training in experimental organic chemistry. All hazardous materials should be handled using the standard procedures for work with chemicals described in references such as "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at

http://www.nap.edu/catalog.php?record_id=12654). All chemical waste should be disposed of in accordance with local regulations. For general guidelines for the management of chemical waste, see Chapter 8 of Prudent Practices.

In some articles in Organic Syntheses, chemical-specific hazards are highlighted in red "Caution Notes" within a procedure. It is important to recognize that the absence of a caution note does not imply that no significant hazards are associated with the chemicals involved in that procedure. Prior to performing a reaction, a thorough risk assessment should be carried out that includes a review of the potential hazards associated with each chemical and experimental operation on the scale that is planned for the procedure. Guidelines for carrying out a risk assessment and for analyzing the hazards associated with chemicals can be found in Chapter 4 of Prudent Practices.

The procedures described in Organic Syntheses are provided as published and are conducted at one's own risk. Organic Syntheses, Inc., its Editors, and its Board of Directors do not warrant or guarantee the safety of individuals using these procedures and hereby disclaim any liability for any injuries or damages claimed to have resulted from or related in any way to the procedures herein.

3. Discussion

β-Lactams are of potential interest as precursors for anti-bacterial and anti-inflammatory agents,

2 building blocks for new biologically active compounds,

3 and as monomers for ring-opening polymerization.

4,5,6,7,8,9,10 β-Lactams of glycals are commonly used method for β-lactam synthesis, produces two new stereocenters. Therefore the product is often a mixture of stereoisomers.

15,16,17 Both the enolate-imine condensation reaction and the Kinugasa reaction rely on substrates that are not readily available or require harsh reaction conditions.

16 In contrast, the alkene-isocyanate cycloaddition method yields β-lactams with high regio- and stereo-selectivity and is compatible with glycal substrates. This reaction proceeds with electron-poor isocyanates (i.e.,

chlorosulfonyl isocyanate (

CSI), p-tolunesulfonyl isocyanate, trifluoroacetyl isocyanate, and trichloroacetyl isocyanate (TCAI)) to yield stereoselective products. synthesized by the: Staudinger's ketene-imine [2+2] cycloaddition reaction;

11 enolate-imine condensation reaction; Kinugasa reaction;

12 and isocyanate cycloadditions.

13,14 Staudinger synthesis, the most

Chmielewski et al. reported synthetic methods to prepare stereoselective sugar vinyl ether β-lactams using TCAI

13 and

CSI.

14 We perform both large scale TCAI and

CSI cycloaddition reactions in our laboratory for the syntheses of β-lactam compounds from a variety of glycal structures (Table 1), including different derivatives of D-glucal (Table 1, entries 1-5), D-galactal (6), D-altral (7) and D-maltal (8). We then use these compounds or monomers for anionic ring-opening polymerization.

Figure 8. Rationale for stereoselectivity of cycloaddition reaction

The procedure described above offers a scalable, operationally simple method for large-scale synthesis of glycal β-lactams using

CSI, which is the most widely used isocyanate cycloaddition reaction for β-lactam synthesis owing to its exceptionally high reactivity and, therefore, the extremely fast cycloaddition reaction.

18 Further, the

CSI cycloaddition reaction is stereoselective due to the concerted addition of the sulfonyl isocyanate on the alkene(predicted by ab initio calculations)

19 as well as the unfavorable stericinteractions between the substituent at the C3 position of the pyranose ring and the incoming

CSI molecule (Figure 8).

14 The stereochemical control in this reaction leads to stereospecific syntheses of β-lactam monomers, ensuring a subsequent stereochemically controlled backbone post anionic ring-opening polymerization.

7,

20Table 1. Substrate scope of CSI and TCAI cycloadditions

Appendix

Chemical Abstracts Nomenclature (Registry Number)

Sodium carbonate; (497-19-8)

Chlorosulfonyl isocyanate; (1189-71-5)

Tri-O-benzyl-d-glucal; (55628-54-1)

Red-Al® sodium bis(2-methoxyethoxy)aluminum hydride solution (>60 wt% solution in toluene); (22722-98-1)

Sodium hydrogen carbonate; (144-55-8)

Sodium sulfate; (7757-82-6)

Hydrogen chloride; (7647-01-0)

Acetone; (67-64-1)

Methanol; (67-56-1)

Toluene; (108-88-3)

|

Maria Varghese received her combined B.S.,M.S. degree (Chemistry major, Biology minor) from Indian Institute of Science Education and Research, Thiruvananthapuram (IISER, TVM), India, where she performed undergraduate research under Professor Kana M. Sureshan. She is currently a Ph.D. Candidate in Professor Mark W. Grinstaff's laboratoryat Boston University. Her doctoral studies focus on the development of synthetic polysaccharide mimetics as synthetic anticoagulants. |

|

Hannah E. Caputo received her Bachelor's degree from the University of New Hampshire in 2014. She completed her M.S. degree under the mentorship of Professors Mark W. Grinstaff and John E. Straub. Her research interests lie in the synthesis, characterization, and modeling of sulfated polysaccharide analogs. |

|

Ruiqing Xiao received his B.S. degree in Material Chemistry (2009) and M.S. degree in Polymer Chemistry and Physics (2012) from Jilin University. His PhD studies focused on the synthesis of biologically active saccharide polymers at Boston University under the supervision of Prof. Mark W. Grinstaff, and he obtained his Ph.D. degree in Organic Chemistry in 2018. Currently, he is working as a post-doctoral researcher in Prof. Robert S. Langer's research group at the Massachusetts Institute of Technology. His research interests include the synthesis of novel immunostimulatory materials and polymeric materials for single-injection vaccine delivery and micronutrient delivery. |

|

Anant Balijepalli attended the University of Michigan and earned a combined B.S.E / M.S.E in biomedical engineering performing research under Dr. Joel Swanson (UM Microbiology) and Dr. Mark Meyerhoff (UM Chemistry). He completed his Ph.D. in biomedical engineering under the mentorship of Dr. Mark W. Grinstaff at Boston University, focusing on the synthesis of cationic poly-amido-saccharides for drug delivery applications. He is currently a Scientist at Vivtex specializing in formulation and assay development to enable oral delivery of biologics. |

|

Aladin Hamoud is a post-doctoral fellow in Prof. Mark W. Grinstaff research group at Boston University. He received his Bachelor's degree from the University of Bordeaux, France in 2013 followed by a Master's degree in organic chemistry in 2015 under the mentorship of Dr. Philippe Piexotto and Prof. Yannick Landais. He received his Ph.D. degree in 2018 under the mentorship of Dr. Valerie Desvergnes developing the aqueous Stetter reaction and the synthesis of nucleolipids for low molecular weight oleogels formation. His current research focuses on the development of mucoadhesive polysaccharide analogs and targeted cancer therapies. |

|

Mark W. Grinstaff is the Distinguished Professor of Translational Research and a Professor of Biomedical Engineering, Chemistry, Materials Science and Engineering, and Medicine at Boston University. Mark received his A.B. from Occidental College, earned his Ph.D. under the mentorship of Kenneth S. Suslick at the University of Illinois, and completed his post-doctoral training with Harry B. Gray at the California Institute of Technology. His current research activities include the synthesis of new macromolecules and biomaterials, self-assembly chemistry, imaging contrast agents, drug delivery, and wound repair. He and his trainees have advanced ideas from the laboratory to the clinic with regulatory approved pharmaceutical and medical device products becoming the standard of care for patients. www.grinstaff.org |

|

Kyohei Oga was born in Kanagawa, Japan. He graduated from Tokyo University of Pharmacy and Life Science in 2021 with B.S. in Life Science under the supervision of Professor Hisanaka Ito. In 2021, he began his graduate studies at the University of Tokyo under the supervision of Professor Masayuki Inoue. His research interests are in the area of the total synthesis of complex natural products. |

|

Masanori Nagatomo completed his Ph.D. (2012) from the University of Tokyo under the supervision of Professor Masayuki Inoue. In 2012, he carried out visiting research with Professor Phil S. Baran at The Scripps Research Institute. In the same year, he was appointed as Assistant Professor in the Graduate School of Pharmaceutical Sciences at the University of Tokyo and was promoted to Lecturer in 2018. His research efforts focus on the development of novel synthetic methodology and applications to the multistep synthesis of complex molecules. |

Copyright © 1921-, Organic Syntheses, Inc. All Rights Reserved